Picture it: You’re in the semiconductor industry and everything moves fast. You have connections with manufacturing facilities across the globe. And your products and strategy are constantly evolving. How do you keep your production humming?

When it comes to cable assemblies, manufacturers in the semiconductor industry are looking for a few things. They need their suppliers to reliably deliver complex work without crimp and soldering issues. To navigate complex supply chains on their behalf. To move fast.

Multi-Tek isn’t new to any of this. For three decades, we’ve been the trusted partner for one of the largest multinational semiconductor chip manufacturers in the world. And we’ve grown with them, centralizing more of their business even as we’ve added new customers across a range of industries.

Here’s the story of how that major multinational semiconductor chip manufacturer saved millions with Multi-Tek.

The multinational started work with Multi-Tek back in 1995, when Multi-Tek was still just a group of five former loggers working out of a garage. Initial projects required machining work. Until the day came when the manufacturer needed something a little different: cable assemblies.

John Overpeck, Owner of Multi-Tek, had wired machinery on his logging equipment before. So he figured he could handle it. And he did: The project was a success, and he was introduced to new contacts at the multinational to take on further work.

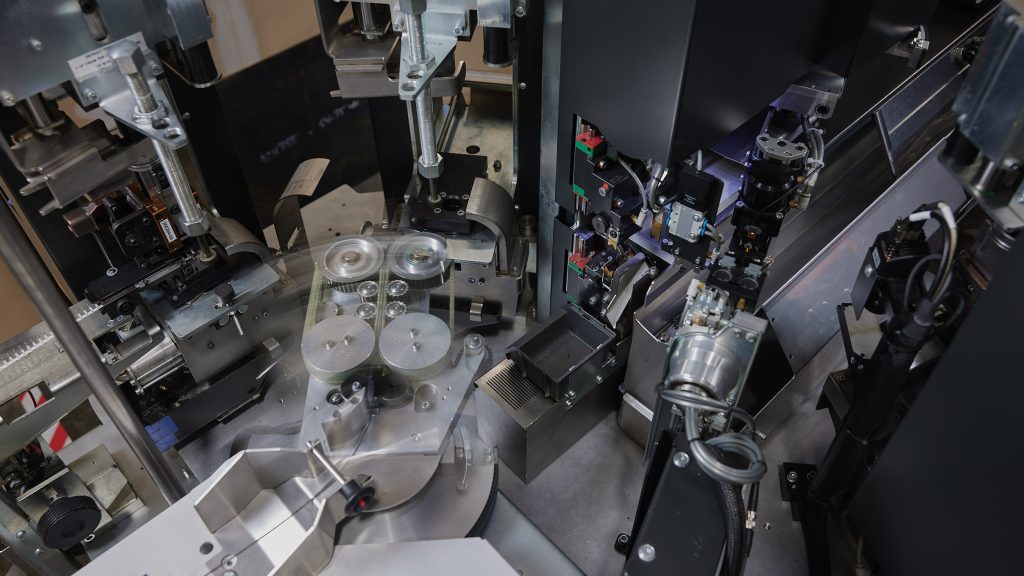

Over those initial years, Multi-Tek worked with the multinational on a wide range of projects that most cable assembly suppliers wouldn’t be set up to handle. An example: In the mid-2000s, Multi-Tek took on a particularly complex project involving complete box builds of chip testers with water manifolds and over 100 different cable assemblies.

Custom cable assemblies are our core competency. But we still have the engineering savviness and creativity that helped us take on a more diverse range of projects back in the day. It allows us to think through the application requirements of your cable assemblies and deliver free design support. And it’s what gave the multinational a reason for initial trust.

R&D moves fast. Which makes a proactive supplier all the more valuable.

Multi-Tek has produced millions of cable assemblies for the multinational, with only one or two minor quality issues within a yearly order of over 100,000 cable assemblies — usually something like a misplaced label. Which is a big distinction from other cable assembly suppliers, where insufficient crimp and soldering quality can lead to product failures.

So the multinational decided to centralize more of its business with Multi-Tek, and we became the point of communication between engineering and purchasing. It made a difference.

When cable assemblies ordered by design engineers weren’t approved for production or required early changes for quality or lead times, we stepped in. As Sales Manager John Ferguson explains, “We’ve saved [the multinational] hundreds of thousands, if not millions of dollars, by telling them, ‘Hold up, you don’t need this.’”

Those savings are the direct result of how we work. A manufacturing engineering manager at the multinational once asked whether Multi-Tek could package and sell the proprietary system we use for handling orders to their other suppliers. Matching Multi-Tek up against his other cable assembly shops, the manager said “My engineers never report any problems with parts from Multi-Tek. You guys just do what you say you’re going to do.”

When that meant entering a complex network of suppliers and manufacturing facilities across the U.S. and Asia to ensure projects were accomplished on time, we handled it.

For large players in the semiconductor industry, suppliers that can navigate complex, global supply chains are a necessity. And it’s a bonus when those suppliers keep an eye out for your business’s best interests, too.

A few years ago, the multinational needed to scale up their already large custom cable assembly orders, quickly. Over the course of three quarters, they needed 5 times as many cable assemblies across 100 different, complex designs. We got to work.

Our state-of-the-art process management allowed us to onboard over 100 new employees without issue. Our unmatched visibility into the cable assembly ecosystem quickly identified parts shortages and circumvented them. And with 100% guaranteed functionality and our 99.8% on-time delivery rate, we kept lines up at the multinational as their business evolved.

Not every supplier the multinational worked with was able to keep up. But Multi-Tek did, further strengthening our processes and capabilities. Which means we could do the same for you.

Think Multi-Tek could be the right fit for your custom cable assembly needs? Then let’s talk. If you’re in the semiconductor equipment industry, we know what it’s like to be a direct supplier to the biggest players and can set you up for success.

We’ll get back to you within a business day, if not sooner. Minimum order quantities start at 100 cable assemblies.

We’ll provide you with a fast quote (standard time is three days, can be as quick as same-day) and recommend manufacturability improvements.

Get a quote for custom cable assemblies