This is part 1 of our four-part series on DfM. See the full series here.

You’re proud of it: A strong cable assembly design, one well-suited to meet the demands of its application. It’s a crucial part of your product — whether you’re getting ready for launch or it’s already on the market.

That pride is called for. But it doesn’t mean there isn’t room for improvement. If you’re like most OEMs, you could likely refine your cable’s manufacturability.

Manufacturability is the difference between robust cable assemblies that arrive on time at a sensible price point and ones that don’t. It’s what keeps you from hundreds of thousands to potential millions lost in production downtime.

Even so, design for manufacturability (DfM) is the missing component for most OEMs outsourcing production of their own custom cable designs. Which makes sense — you don’t interface directly with wiring distributors or know which connector series are further along in their lifecycle. It’s not your job to master the cable assembly ecosystem.

It’s ours. So in this series, we’re going to share what we know. Here, in Part 1, we’ll introduce you to cable assembly DfM.

Picture a cable assembly Venn Diagram. The perfect cable assembly design will optimize for three factors: robustness, lead time and price.

Most designs make tradeoffs and generally sacrifice lead times or affordability to guarantee functionality. You might, for instance, ensure robustness by sourcing a specialized connector that increases your price and is susceptible to shortages.

Your logic is sound: Reliability isn’t something you can ever cut corners on. But it’s not always a necessary sacrifice.

Overengineering cable assemblies is endemic within the industry. Sometimes it happens because of anxiety — engineers don’t know what material or process substitutions create risk. Sometimes it happens as a slip-up, like an overzealous approach to DigiKey’s search filter function.

Stop overengineering cable and leaving gains in robustness, cost or lead time on the table. It’s time to start thinking about DfM and improving your cable’s manufacturability. We can help with that.

The most impactful DfM insights emerge from knowledge of the cable assembly ecosystem. That takes a savvy insider. But there are still basic principles anyone can adopt.

Your cable assembly might require extremely specific, niche components. But if it doesn’t, quoting these components will force you to take on risk with availability and lead times that you don’t need to. Distributors simply don’t carry inventory that’s likely to sit on the shelf. Choosing standard parts for your cable assembly is a key step towards surety of supply.

But if you’re not totally fluent in the ins-and-outs of cable assembly component equivalents, what do you do? What parts are standard in the cable assembly industry isn’t public or (to our knowledge) even previously published information. But we’ve included a list of standard components in Part 2 of this series, along with more technical information on how to draw up a smarter BoM.

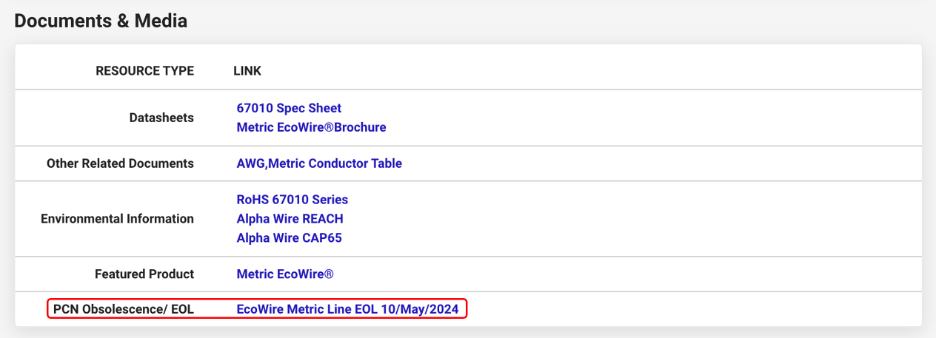

Additionally, you’ll want to keep in mind the potential for a component to be discontinued. Using standard parts, this isn’t likely. But specialized parts present some risk here.

Generally, components from a large, reputable manufacturer are less likely to suddenly go EOL. And you might be able to find plans for discontinuation on DigiKey, under the resources sections (see Documents & Media) located at the bottom of the product page.

The BoM isn’t the only place where DfM principles matter. An example: A drawing specified wires that were twisted far tighter than usual for an assembly of this style. After flagging the observation to the OEM, we confirmed a process alteration with their engineering team. The result was a more robust cable assembly that didn’t risk damage to the wires.

If you’re working with a reputable supplier, being overly specific on processes generally works to your detriment. They’re building to IPC/WHMA-A-620 standards and follow industry best practices. Deviations from those best practices can risk reliability and increase cost unnecessarily.

And, of course, another place to begin is with more research. Part 3 of this series provides a video walkthrough of common DfM adjustments. You can also check out our list of common design mistakes.

Here’s the thing: They almost certainly won’t.

Cable assembly suppliers almost never collaborate with OEMs on their cable designs. Most are uninterested in the end use of the cable assemblies they produce. So they act accordingly: They quote what somebody has handed them per the print, rather than investigating ways to improve their customers’ work.

Multi-Tek is the exception. You send us a drawing and BoM and we get back to you with suggested improvements. We work out a final design with your engineering team and get to work. It’s partnership that goes beyond a standard vendor relationship.

Another factor to consider: The level of technology your supplier employs. State-of-the-art automated crimping technology makes certain designs, especially those using small-gauge wires, scalable for mass production. A small mom-and-pop cable house simply won’t be able to mass produce those kinds of cable assemblies with hand tools.

DfM has the potential to radically improve the reliability of your product and the stability of your production. So it’s worth checking with an expert to see how it can be incorporated into your cable assemblies.

Then let’s do it. Fill out our form and we’ll get back to you within a business day — likely within a few hours. We love talking shop.

We’ll provide you with a fast quote (standard time is three days, can be as quick as same-day) and recommend manufacturability improvements.

Get a quote for custom cable assemblies