This is Part 4 of our four-part series on design for manufacturability. See the full series here.

It takes time for manufacturers to build trust with their best customers. For a pump manufacturer serving industrial clients, products absolutely must deliver every time. And that takes better cable assembly design.

An industrial pump manufacturer had spent 75 years building a loyal base for their high-quality pumps. But they knew that reputation was at stake when launching an IoT pump line in 2020.

The manufacturer has a small, dedicated team, and its employees, including one of their sales managers, leverage a broad skillset across a range of projects. But they didn’t have enough cable assembly expertise to make sure the harnesses their pumps relied on were both durable and cost-effective. As the sales manager put it:

“We build pumps, so electrical harnesses are not our specialty. Finding vendors that are able to fill those gaps for us and bring their expertise to the table is one of the reasons why we work a lot with Multi-Tek.”

Read on to find out how this industrial pump manufacturer scaled from 100 to over 4000 pumps in the field — and took advantage of Multi-Tek’s expertise in designing for manufacturability (DfM) to do so.

Talking to customers in the field, the sales manager noticed something early into the launch of their new product line — high-quality pumps weren’t enough.

Customers wanted a plug-and-play, user-friendly pump solution that had all the necessary components out of the box. Customers didn’t want to make a trip to Home Depot to pick up additional wiring.

So the pump manufacturer started manufacturing harnesses in-house. But they quickly realized they were in over their heads:

“It wasn’t sustainable for us to do it internally. It’s not what we do, and we don’t have the tools or the personnel.”

That’s when they reached out to us. For the sales manager, what stood out about Multi-Tek is the reliability of our cable assemblies: While the team at the pump manufacturer has to inspect and test shipments from other vendors to make sure they work appropriately, the only time they test Multi-Tek harnesses is when they receive a prototype.

So why is Multi-Tek custom cable so reliable? It’s partly due to a relentless focus on quality control. And partly because of DfM.

Early into their relationship, the sales manager was impressed by Multi-Tek’s responsiveness and clear communication. So he started turning to Multi-Tek for design support. As a result, the harnesses became more manufacturable, using materials with consistent supply that can scale.

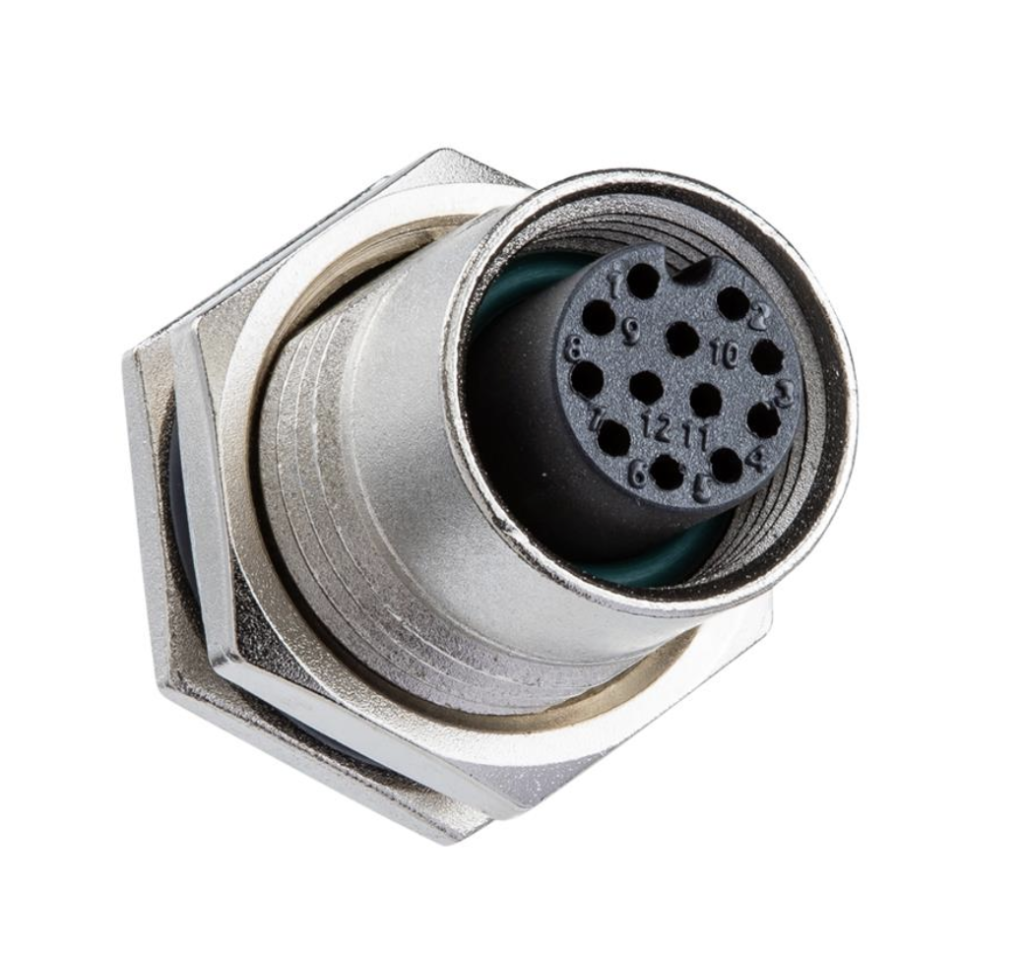

Here’s how that design support played out. The IoT pumps use M12 connector systems as the central receiving station for all the other devices connected to the harness. They’re great for achieving the simplified, plug-and-play device that the sales manager knew his customers were looking for.

But working with M12s can be tricky. Custom injection molded M12 cables, ordered to the specific lengths and breakouts needed to reach the devices being monitored and controlled, come with high costs and long lead times.

We worked together with the sales manager on a hybrid cable solution that combined the convenience offered by high-density pin count M12 connectors with Deutsch DT series connectors. Cost-effective and water-resistant, Deutsch connectors are already widely used in the transportation industry. But they work just as well for outdoor pumps.

Other material substitutions cut raw cable costs in half. Multi-Tek kept the sales manager’s team from overengineering solutions and steadied focus around an effective, manufacturable design.

With Multi-Tek’s consistent, affordable cable assemblies and fast lead times backed by a commitment to DfM, he found a partner he could rely on. “Peace of mind,” the sales manager says, “is probably one of the biggest reasons we don’t really look elsewhere.”

Three years into their partnership with Multi-Tek, the sales manager took a tour of our facility in Portland.

While the trip was originally meant to build on the business relationship, we were able to work out additional improvements to his harness design that would reduce overall cost — including the cost of the M12 integration. Designing for greater manufacturability has become a standard means of product improvement.

The sales manager’s partnership with Multi-Tek has grown alongside the success of his IoT lines. His company’s orders have increased by 350% since we started our partnership, and they’re already planning for further growth down the line:

“One of the things that we’re looking at doing with Multi-Tek next year is potentially doing larger stocking orders, now that we’ve got some history of the product and we’ve got some kind of consistency to the sales.”

Manufacturers turn to Multi-Tek for their wire harness needs because they know expertise matters when it comes to producing consistently reliable, affordable equipment.

To talk to an expert about your application requirements, just reach out. Minimum order quantities start at 100 cable assemblies. We’ll be in touch within a business day, if not sooner, and will help you figure out next steps.

We’ll provide you with a fast quote (standard time is three days, can be as quick as same-day) and recommend manufacturability improvements.

Get a quote for custom cable assemblies