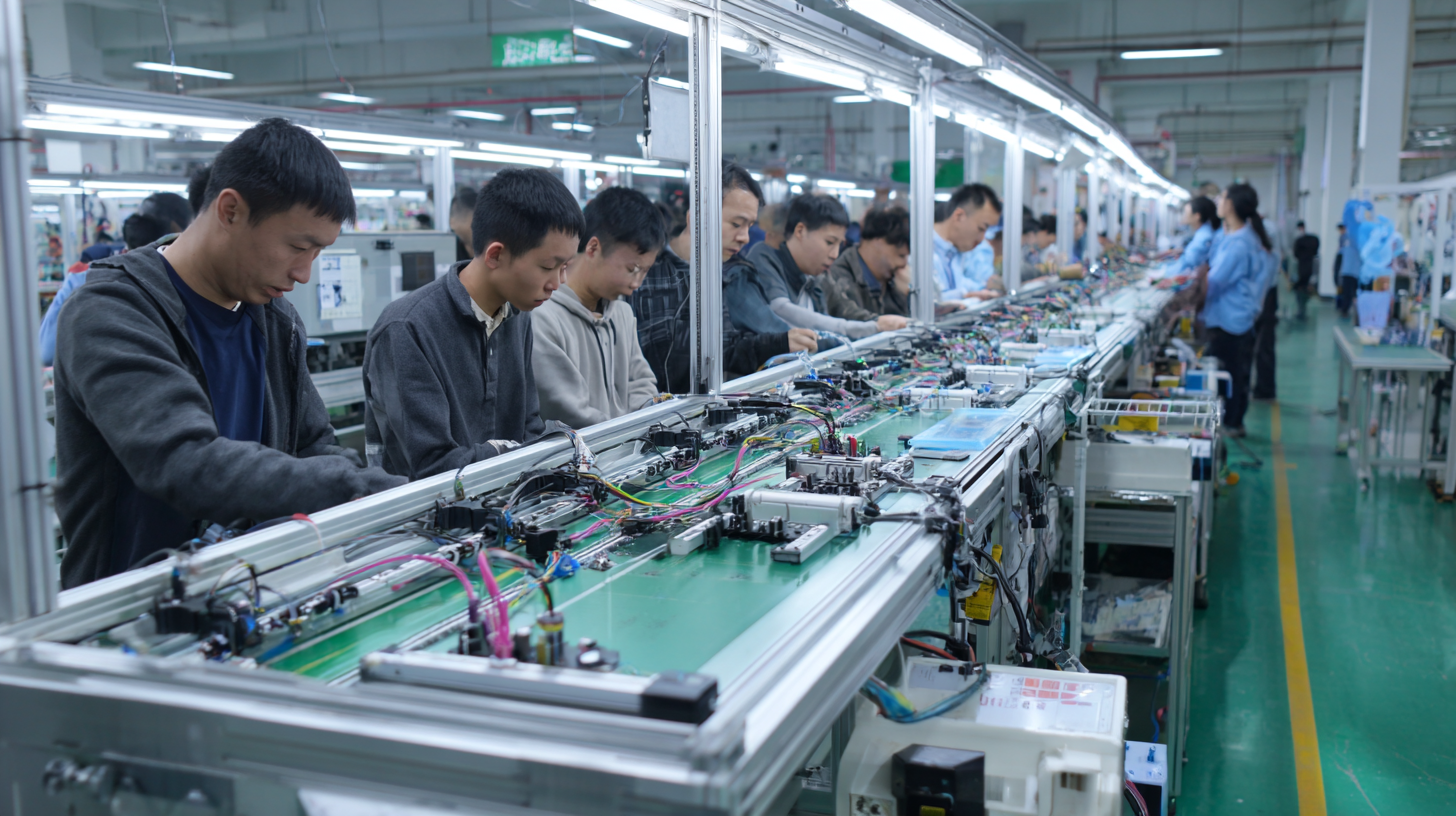

The wire harness assembly process is a critical component in various industries, including automotive, aerospace, and consumer electronics, playing a pivotal role in ensuring the functionality and reliability of electrical systems.

The wire harness assembly process is a critical component in various industries, including automotive, aerospace, and consumer electronics, playing a pivotal role in ensuring the functionality and reliability of electrical systems.

According to a recent report by Research and Markets, the global wire harness market is projected to reach $66.5 billion by 2025, driven by the increasing demand for advanced vehicle technologies and rising automation in manufacturing processes.

The 138th Canton Fair in 2025 will serve as a significant platform for industry stakeholders to explore innovations and best practices within this assembly process. With attendees eager to exchange insights about cutting-edge manufacturing techniques and advancements in materials, this event promises to provide a comprehensive overview of emerging trends that are set to shape the future of wire harness production.

As we delve into the latest developments, it is essential to understand how improvements in the wire harness assembly process can enhance overall product efficiency and performance in today's fast-paced market.

At the upcoming 138th Canton Fair in 2025, wire harness technology is set to take center stage with a focus on innovations that enhance efficiency and sustainability in manufacturing. Industry leaders are expected to showcase advancements that integrate smart technology, offering solutions that are increasingly tailored to meet the demands of modern industries. This is a pivotal moment for the wire harness sector, which plays a crucial role in sectors ranging from automotive to telecommunications.

The innovations highlighted at the fair align with broader trends in technology, reflecting a shift towards incorporating AI and data analytics into manufacturing processes. As industries strive for greater efficiency, the emphasis on AI-powered solutions and smart automation within wire harness assembly is likely to transform traditional practices. This evolution not only aims to improve production capabilities but also emphasizes the importance of sustainability, resonating with global movements towards environmentally friendly practices in manufacturing.

The 138th Canton Fair in 2025 showcased significant advancements in wire harness assembly processes, emphasizing automation and efficiency. The latest technologies have enabled manufacturers to significantly reduce assembly time while enhancing precision. One standout innovation includes the integration of robotic systems, which streamline repetitive tasks and minimize the risk of human error. These automated solutions not only improve production rates but also allow for more consistent quality across products.

Another key trend observed at the fair is the increasing emphasis on sustainability in wire harness assembly. Many exhibitors highlighted the use of eco-friendly materials and processes that reduce waste and energy consumption. This shift aligns with global industry standards focused on reducing environmental impact. Additionally, the adoption of modular assembly designs allows for greater flexibility and adaptability in production, catering to diverse market needs without compromising on sustainability goals. As these trends continue to evolve, they are set to redefine the wire harness manufacturing landscape significantly.

| Trend | Description | Impact on Industry | Innovation Type |

|---|---|---|---|

| Automation Integration | Increased use of robots in assembly lines for higher efficiency. | Reduces labor costs and enhances precision. | Process Innovation |

| Sustainable Materials | Adoption of recyclable and eco-friendly materials in wire harnesses. | Improves eco-friendliness and market acceptance. | Material Innovation |

| Digital Twin Technology | Utilizing digital twins for real-time monitoring of assembly processes. | Enhances troubleshooting and quality assurance. | Technology Innovation |

| Customization Trends | Growing demand for custom wire harness solutions to meet specific client needs. | Increases customer satisfaction and loyalty. | Service Innovation |

The wire harness industry is witnessing a dynamic landscape shaped by both domestic and international manufacturers. According to a recent report by Research and Markets, the global wire harness market is expected to reach $80 billion by 2025, with a compound annual growth rate (CAGR) of 5.7%. This robust growth is driven by increasing demands across automotive, aerospace, and industrial sectors.

At the 138th Canton Fair in 2025, manufacturers from China showcased innovative assembly techniques, emphasizing automation and precision in wire harness production, which significantly enhance efficiency and reduce labor costs.

At the 138th Canton Fair in 2025, manufacturers from China showcased innovative assembly techniques, emphasizing automation and precision in wire harness production, which significantly enhance efficiency and reduce labor costs.

In contrast, foreign manufacturers, particularly from Germany and Japan, are emphasizing quality and technological advancements. For example, a study published by the International Wire & Cable Symposium highlighted that European firms are adopting advanced materials and low-weight designs to meet the stringent requirements of electric vehicles (EVs) and other industries.

While Chinese manufacturers often focus on mass production, optimizing costs, they are increasingly incorporating advanced technologies to compete in quality and innovation. This comparative analysis showcases the strengths and challenges faced by manufacturers across borders, aiming to drive improvements and foster collaboration in the wire harness assembly process.

The wire harness industry is undergoing significant transformations, especially as showcased at the 138th Canton Fair in 2025. Industry experts emphasized that with the rise of electric vehicles (EVs), the demand for advanced wire harness solutions is projected to grow by 15% annually. This surge is primarily driven by the need for more efficient and lightweight materials that facilitate better energy transmission and support intricate designs. According to a recent market report by Market Research Future, the global wire harness market is expected to reach USD 76.73 billion by 2025, highlighting the urgency for innovation and improved manufacturing processes.

Tips: To stay competitive, manufacturers should prioritize investing in automated assembly technologies. Automation not only increases production efficiency but also enhances the precision of wire harness assembly, reducing human error. Additionally, embracing eco-friendly materials for wire harnesses can position companies favorably in a market that increasingly values sustainability.

As we look to the future, the integration of smart technologies such as IoT-enabled wire harnesses will become crucial. These innovations will allow for real-time monitoring of electrical systems, thus improving reliability and maintenance in various applications, including automotive, aerospace, and industrial machinery. Leveraging these insights can help companies navigate the evolving landscape and meet the growing demands of their clients efficiently.

The 138th Canton Fair in 2025 offers a unique platform for professionals in the wire harness sector to explore innovative technologies and foster collaboration. Attendees can engage in meaningful networking opportunities that facilitate the exchange of ideas and best practices. The fair creates an environment where manufacturers, suppliers, and industry experts can connect, allowing for the discovery of potential partnerships that can enhance productivity and drive growth within the sector.

In addition to networking, the Canton Fair highlights key trends in collaboration that are shaping the wire harness industry. As companies increasingly seek to integrate advanced manufacturing techniques and sustainable practices, the interactions fostered at the fair can lead to joint ventures and strategic alliances. These collaborations not only enhance operational efficiency but also help in developing cutting-edge solutions to meet evolving market demands. The event thus serves as a vital hub for professionals aiming to stay ahead in a rapidly changing industry landscape.

This chart illustrates the percentage distribution of innovations and trends observed in the wire harness assembly sector at the 138th Canton Fair in 2025. The data highlights key areas of focus including automation, materials used, and integration of smart technologies.