In today's rapidly advancing technological landscape, the demand for reliable connectivity solutions is paramount, making wire and cable assemblies integral to various industries. These assemblies serve as the backbone for numerous applications, from automotive and telecommunications to renewable energy and industrial automation. According to a recent market research report by Allied Market Research, the global wire and cable assembly market is projected to reach $250 billion by 2027, growing at a CAGR of 5.3%. This growth underscores the critical role that wire and cable assemblies play in facilitating efficient connectivity.

The proliferation of smart devices and the Internet of Things (IoT) has further intensified this demand, compelling manufacturers to adopt innovative designs and materials to enhance performance and reliability. Statistics from the Wiring Harness Manufacturers Association indicate that the automotive sector alone accounted for approximately 40% of the wire and cable assembly market in 2022, highlighting the importance of these components in modern vehicles, particularly with the rise of electric vehicles and autonomous technology. This introduction delves into the various types of wire and cable assemblies that optimize connectivity solutions, ensuring they meet the evolving needs of diverse applications across multiple industries.

Wire and cable assemblies play a crucial role in ensuring reliable connectivity across various industries. In the automotive sector, for example, these assemblies facilitate seamless communication between electronic components, enabling functions such as advanced driver-assistance systems and infotainment features. The wiring harnesses in modern vehicles are engineered to withstand harsh environments and vibrations, ensuring safety and performance. Their ability to integrate multiple connections into a single streamlined assembly enhances efficiency and reduces the potential for faults, ultimately improving vehicle reliability.

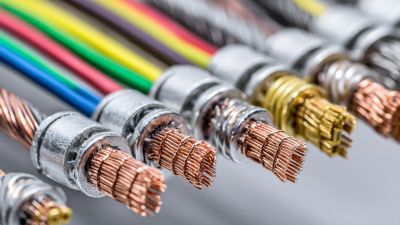

In the telecommunications industry, wire and cable assemblies support the backbone of data transmission. Fiber optic cables, for instance, are increasingly used for high-speed internet connections, offering faster data transfer rates and greater bandwidth. These assemblies must be meticulously designed to minimize signal loss and interference, ensuring optimal performance. Additionally, in the industrial sector, robust cable assemblies are essential for powering machinery and facilitating automation processes. Custom configurations tailored to specific applications ensure that they meet the rigorous demands of manufacturing environments, ultimately driving productivity and reducing downtime.

Efficient connectivity solutions are essential components in modern electronic systems, ensuring that data transmission remains reliable and fast. One of the key benefits of these solutions is their ability to support high-speed communication across various devices and networks. This is particularly important in environments where time-sensitive data transfer is critical, such as in telecommunications, data centers, and industrial automation. By utilizing advanced wire and cable assembly types, organizations can significantly reduce latency and enhance overall system performance.

Another significant advantage is the improved signal integrity that advanced connectivity solutions provide. Quality wire and cable assemblies minimize electromagnetic interference and optimize the transmission medium, which leads to fewer errors and disruptions during data exchange. This reliability fosters greater operational efficiency and can lead to lower maintenance costs over time. Moreover, with the rise of smart technologies and the Internet of Things (IoT), the demand for flexible and scalable connectivity options has increased. Efficient connectivity solutions offer the adaptability needed to meet these evolving requirements, ensuring that systems can grow and evolve alongside technological advancements.

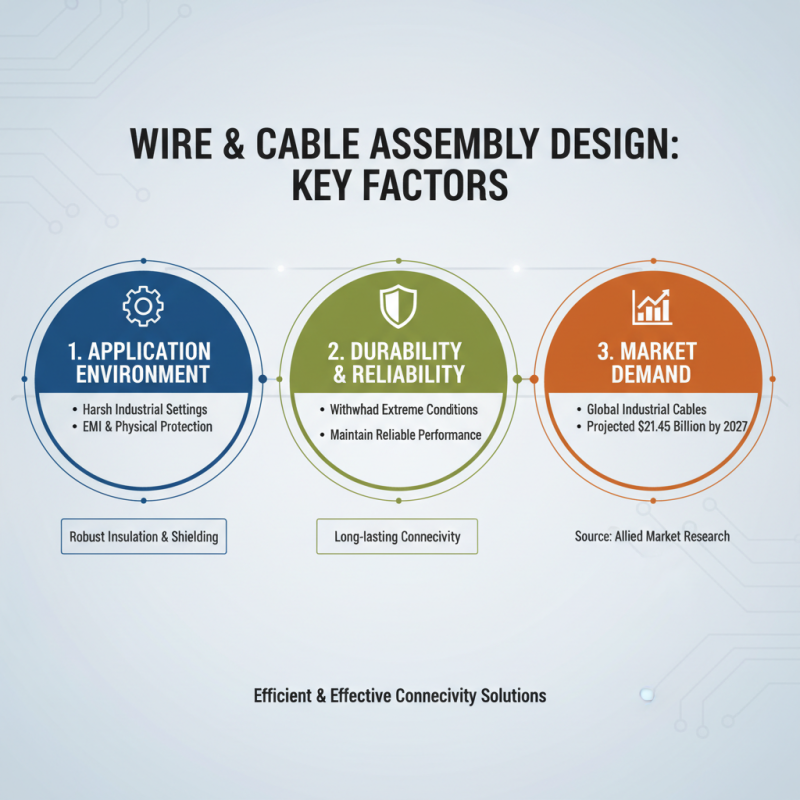

When designing wire and cable assemblies, several critical factors come into play that can significantly influence the efficiency and effectiveness of connectivity solutions. One of the primary considerations is the intended application environment. For instance, assemblies used in harsh industrial settings may require robust insulation and shielding to protect against electromagnetic interference (EMI) and physical damage. According to a report from Allied Market Research, the global demand for industrial cables is projected to reach $21.45 billion by 2027, reflecting the necessity for durable assemblies that can withstand extreme conditions while maintaining reliable performance.

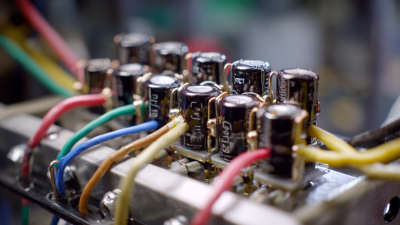

Another important factor is the selection of materials. The type of conductor, insulation, and jacket materials can greatly impact the assembly's performance characteristics such as flexibility, temperature tolerance, and signal integrity. A comprehensive survey conducted by Grand View Research highlights that the market for wire and cable materials is expected to grow significantly, driven by advancements in low-smoke, zero-halogen (LSZH) materials. These materials are particularly valuable in applications where safety and environmental considerations are paramount, as they minimize hazardous emissions in case of fire.

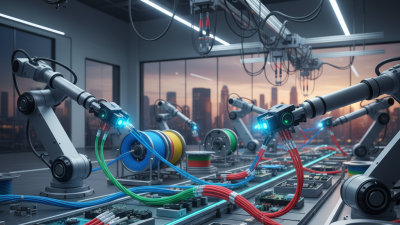

Additionally, the design and manufacturing processes themselves can influence assembly performance. Precision in manufacturing tolerances and the quality of connections are critical for minimizing signal loss and maximizing longevity. According to a study by IDTechEx, the integration of automated manufacturing processes in cable assembly can enhance consistency and reliability. As industries continue to prioritize efficiency and performance, understanding these influencing factors in wire and cable assembly design will be essential for meeting the evolving connectivity demands.

When selecting wire and cable assemblies, it is crucial to consider several best practices to ensure optimal performance and reliability. First, assess the specific requirements of your application, including voltage, current, and environmental conditions. This analysis helps determine the appropriate wire gauge, material type, and insulation, which significantly affect both durability and electrical performance.

Another essential practice is to prioritize the quality of connectors and assembly methods. High-quality connectors ensure secure and stable connections, minimizing signal loss and interference. Additionally, evaluating techniques such as soldering versus crimping can impact the lifespan and reliability of the assembly. It’s advisable to seek manufacturers who adhere to industry standards and can provide detailed specifications for their products, ensuring that the assemblies will meet your performance expectations while offering long-term reliability.

As the demand for high-speed and reliable connectivity continues to grow, the wire and cable assembly industry is evolving rapidly. Future trends indicate a shift towards more integrated solutions that prioritize not only functionality but also adaptability. Innovations such as hybrid cables combining power and data lines are gaining traction, allowing for streamlined installations and reduced complexity in various applications, from telecommunications to industrial automation. Additionally, advancements in materials and manufacturing processes are paving the way for assemblies that can withstand extreme environmental conditions while maintaining performance.

Tips: When designing or selecting wire and cable assemblies, consider future-proofing your installations by opting for modular systems. This can greatly enhance flexibility, allowing for easy upgrades and expansions as technology advances.

Another significant trend is the rise of smart cables equipped with sensors that provide real-time data on performance and diagnostics. These smart assemblies facilitate proactive maintenance and improve overall reliability. As the Internet of Things (IoT) continues to expand, the need for such intelligent solutions will become imperative for staying competitive.

Tips: Before making any purchasing decisions, conduct a comprehensive analysis of your connectivity needs. This will ensure you choose the right cable assembly that not only meets current requirements but also supports future innovations.