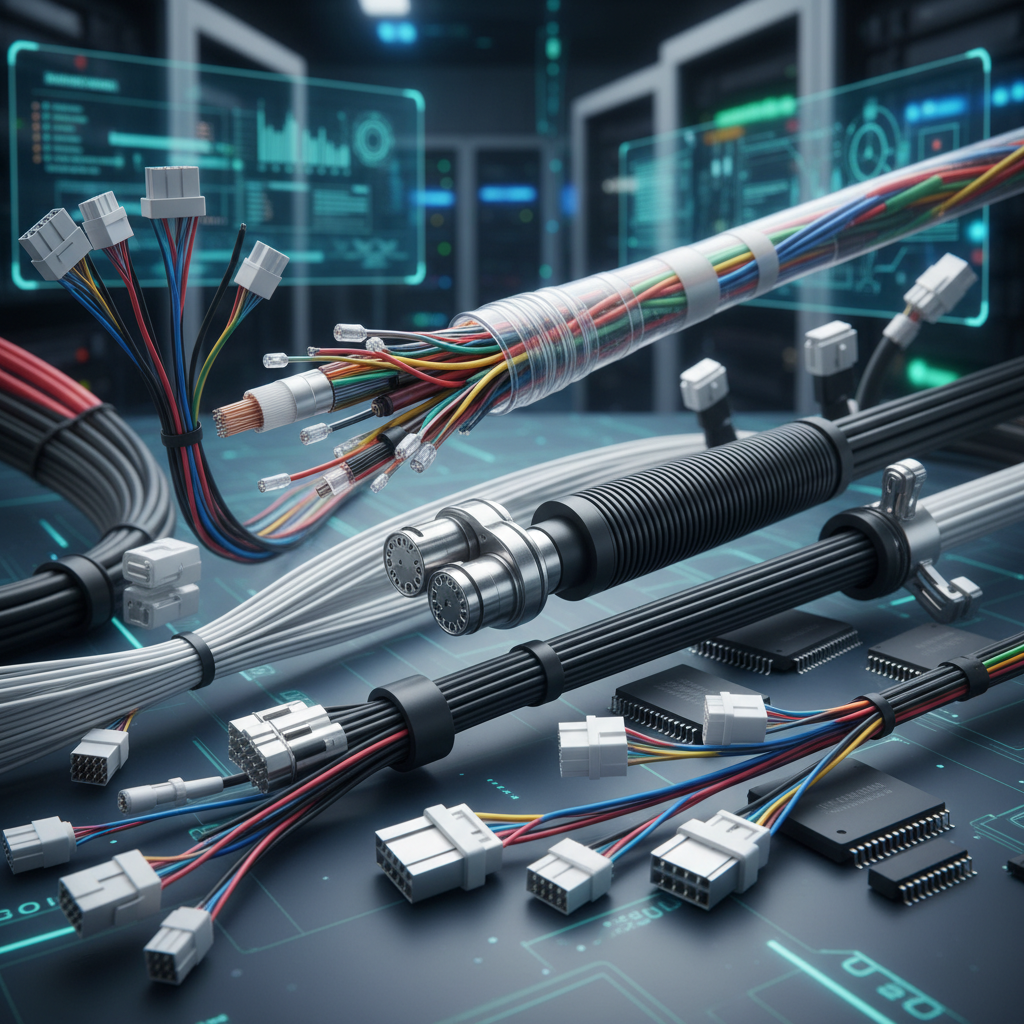

In the ever-evolving landscape of technology, the demand for seamless connectivity solutions is at an all-time high. Among the myriad components that facilitate efficient communication and power distribution, wire assemblies stand out as essential elements that enhance the performance and reliability of various systems. From consumer electronics to industrial equipment, the significance of high-quality wire assemblies cannot be overstated, as they form the backbone of modern connectivity solutions.

With advancements in materials and manufacturing techniques, wire assemblies have transformed into sophisticated solutions that cater to specific needs across diverse applications. Selecting the right wire assemblies can significantly impact the efficiency, durability, and overall functionality of devices. In this article, we will explore the top 10 wire assemblies that you need to consider for enhanced connectivity solutions, focusing on the features that make them indispensable for both everyday and specialized applications. By understanding the unique advantages of these wire assemblies, you can make informed choices that will elevate your projects and improve operational performance.

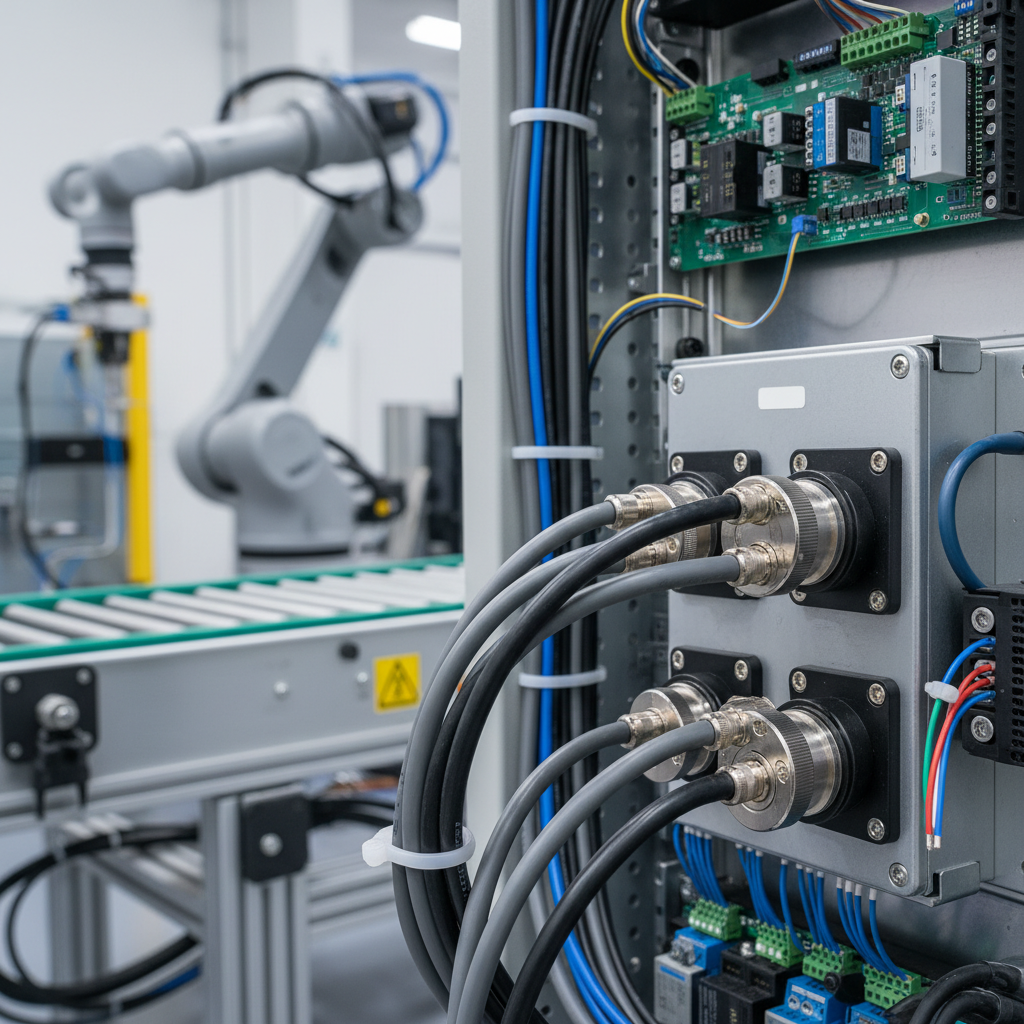

Wire assemblies are essential components in a variety of connectivity solutions across different industries, particularly in automation, industrial communication, and drive technology. Notably, M12 panel mount connectors exemplify how these assemblies provide flexibility in system designs while ensuring robust and reliable connections. Their standardized form factor and compact design make them ideal for use in tight spaces, allowing seamless integration into various automation systems.

As the demand for enhanced connectivity grows, the cable assembly market is projected to expand significantly, indicating a shift towards more efficient and reliable solutions. With a market size estimated to reach USD 253.81 billion by 2030, innovations in wire assembly types—including RF cables, cable assemblies, coaxial adapters, and connectors—are driving this growth. The increasing trend towards automation and advanced industrial communication systems further emphasizes the importance of reliable wire assemblies in ensuring connectivity and performance in modern applications.

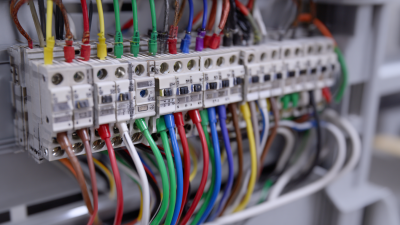

When it comes to selecting wire assemblies for enhanced connectivity solutions, several key features should be meticulously considered to ensure optimal performance. Firstly, the material composition is crucial; wires made from copper or high-quality alloys tend to offer superior conductivity, which can significantly reduce signal loss. Additionally, consider the insulation type used. PVC and TPR are common options, but for extreme environments, materials like silicone or rubber may provide better durability and resistance to temperature fluctuations.

Another critical aspect is the assembly design, which directly affects installation and maintenance. Look for wire assemblies that support modular designs, allowing for easy upgrades and modifications without the need for complete re-wiring. Furthermore, the gauge of the wire should be tailored to the specific application, as thicker wires can handle higher currents but may also be less flexible. Lastly, certification and compliance with industry standards should never be overlooked; ensuring that the wire assemblies meet relevant standards guarantees both safety and reliability in their application.

In the rapidly evolving landscape of modern electronics, wire assemblies play a crucial role in ensuring robust connectivity solutions across various applications. According to a report from Grand View Research, the global wire harness market is projected to reach $64.1 billion by 2025, highlighting the significant demand for efficient wire assembly solutions. These assemblies are extensively used in industries such as automotive, telecommunications, and consumer electronics, where reliable connections are essential for device performance.

In automotive applications, wire assemblies are integral to the functioning of critical systems such as infotainment, safety, and engine management. Industry data indicates that over 1,000 individual connections can be found in a modern vehicle, underscoring the importance of high-quality wire assemblies that can withstand vibration and temperature fluctuations. Furthermore, with the rise of electric and hybrid vehicles, the need for customized wire assemblies that can handle higher power loads is becoming increasingly evident. Similarly, in consumer electronics, the demand for compact and efficient wire assemblies is driving innovation as manufacturers strive to create thinner and lighter products without compromising on connectivity quality.

High-quality wire assemblies play a crucial role in enhancing connectivity solutions across various industries. One of the primary benefits of using superior wire assemblies is their ability to significantly reduce signal loss. This ensures that data transmission remains efficient and reliable, which is essential for applications ranging from telecommunications to industrial machinery. With stronger insulation and better conductivity, high-quality wire assemblies can withstand environmental stressors, resulting in longer lifespans and reduced maintenance costs.

Moreover, utilizing top-tier wire assemblies fosters improved safety. Quality materials and precise manufacturing processes minimize the risks associated with short circuits and electrical failures. As a result, businesses can avoid costly downtimes and enhance the overall safety of their operations. Furthermore, with customizable options available, high-quality wire assemblies can be tailored to meet specific operational requirements, ensuring optimal performance and connectivity for various applications. The investment in premium wire assemblies not only boosts operational efficiency but also provides peace of mind through enhanced safety standards.

| Wire Assembly Type | Key Features | Applications | Benefits |

|---|---|---|---|

| Custom Cable Assemblies | Tailored lengths, various connectors | Electronics, Robotics | Improved reliability, exact fit |

| Molex Assemblies | Portable, high-speed capability | Consumer Electronics, Automotive | Enhanced performance, space-efficient |

| Wire Harnesses | Multiple wires in a single bundle | Industrial Machinery, HVAC | Reduced clutter, simplified installation |

| Ribbon Cable Assemblies | Flat, flexible design | Computers, Printers | Space-saving, easy to route |

| Flat Cables | Low-profile, lightweight | Telecommunications, Networking | Flexibility, easy installation |

| Coaxial Cable Assemblies | Shielded design for noise reduction | Television, Radio | Excellent signal quality |

| USB Cable Assemblies | Fast data transfer, various types | Computers, Mobile Devices | Universal compatibility, high speed |

| HVAC Wire Assemblies | Durable, weather-resistant materials | Heating and Cooling Systems | Longevity, reliability in harsh conditions |

| Automotive Wire Harnesses | Customized for vehicle specifications | All automotive applications | Safety, durability, performance |

| Signal Cables | High-fidelity signal transfer | Audio, Video Systems | Clarity, low signal loss |

The wire assembly industry is witnessing significant innovations that enhance connectivity solutions and performance. According to a recent market report by Grand View Research, the global wire and cable assembly market is expected to reach USD 227.1 billion by 2027, advancing at a compound annual growth rate (CAGR) of 5.5%. This surge is driven by the increasing demand for advanced connectivity solutions in sectors such as telecommunications, automotive, and consumer electronics.

One of the most innovative trends in wire assembly technology is the integration of advanced materials and manufacturing techniques. For instance, companies are increasingly utilizing lightweight materials like nylon and advanced plastic composites, which not only reduce weight but also improve durability and flexibility. Additionally, the rise of automation in production has enabled manufacturers to achieve more precise connections with reduced human error, further enhancing performance metrics. The adoption of modular designs in wire assemblies is another trend, allowing for easier upgrades and maintenance while supporting the growing Internet of Things (IoT) applications. These technologies are not just improving reliability but also addressing the increasing complexity of modern connectivity requirements.

This bar chart presents the performance ratings of the top 10 wire assemblies essential for enhanced connectivity solutions. Each assembly type is evaluated on a scale from 0 to 100, indicating its effectiveness in modern connectivity applications.