In an increasingly competitive manufacturing landscape, selecting the right wire harness manufacturing equipment is pivotal to ensuring efficiency, quality, and cost-effectiveness. According to a report by MarketsandMarkets, the wire harness market is projected to reach USD 78.57 billion by 2025, driven by the growing demand in industries such as automotive, aerospace, and telecommunications. As manufacturers strive to meet these rising demands while navigating challenges like technological advancements and supply chain disruptions, the choice of manufacturing equipment becomes more critical than ever. Companies must consider various alternatives that not only align with their production needs but also enhance their operational capabilities. This blog will delve into five essential tips for choosing the best wire harness manufacturing equipment, ensuring that businesses can adapt and thrive in this dynamic environment.

When evaluating wire harness manufacturing equipment, the quality of the machinery is paramount. First and foremost, consider the precision of the equipment. High-quality machines should offer superior accuracy in cutting, crimping, and assembling wires and connectors. This precision not only ensures that the wire harnesses meet stringent industry standards but also significantly reduces waste and rework, ultimately boosting your production efficiency.

Additionally, durability and reliability are critical factors. Look for equipment built from high-grade materials designed to withstand the demands of a high-volume production environment. Machines that require frequent repairs can slow down your operation and lead to increased costs. Moreover, assess the ease of maintenance and availability of spare parts. Equipment that is user-friendly and comes with robust support can greatly enhance productivity and reduce downtime. By focusing on these key considerations, you can select equipment that not only meets your current needs but also supports your future growth and innovation in wire harness manufacturing.

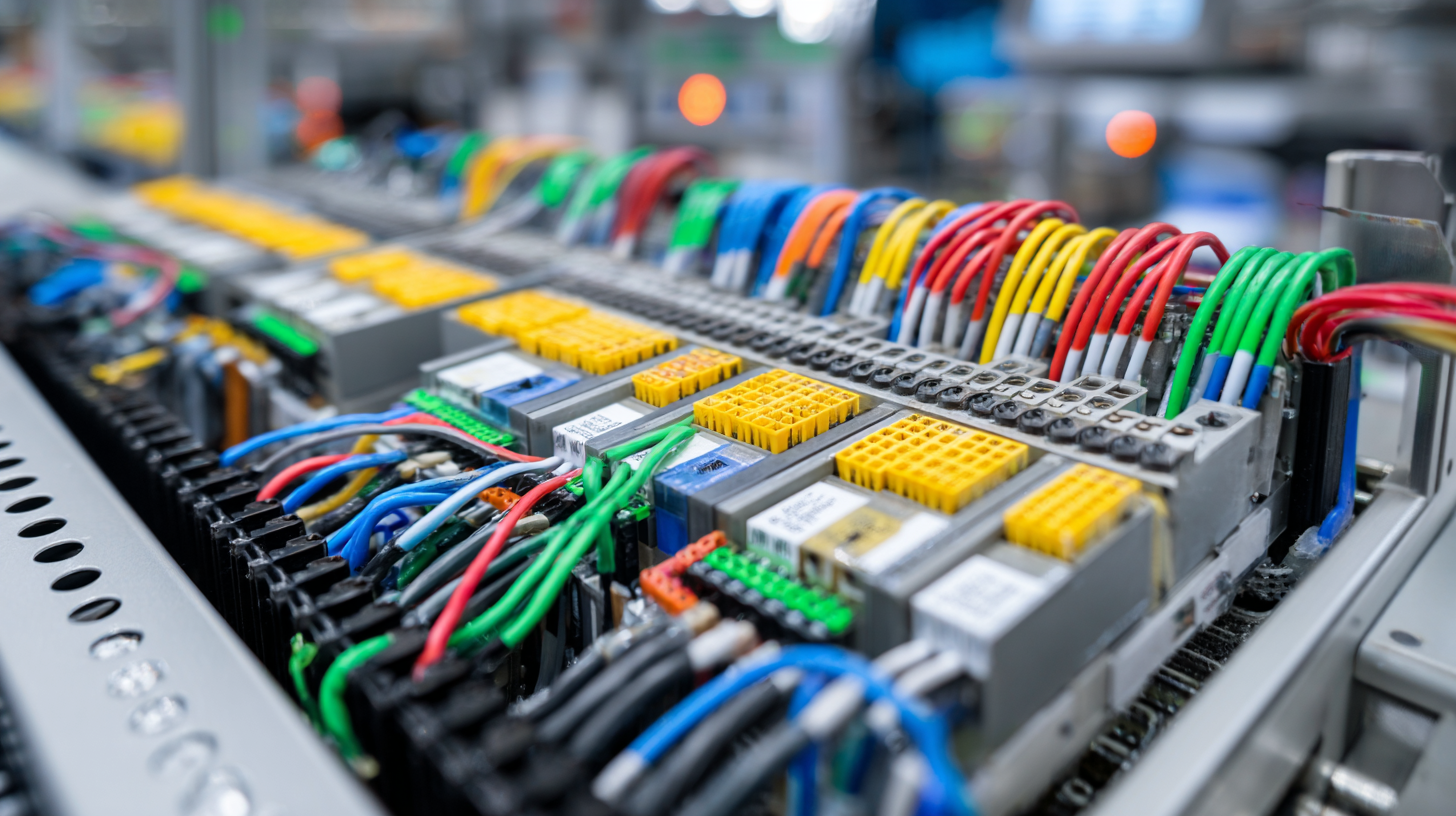

When it comes to wire harness manufacturing, selecting the right equipment is crucial to ensuring efficiency and quality in production. Understanding the different types of wire harness manufacturing equipment available can help businesses streamline their processes and meet specific needs. Common types include automatic cutting machines, which enhance precision by cutting wires to the exact lengths required, and strippers, which remove insulation from wires without damaging the conductor. Both of these tools are integral for preparing wire components for assembly.

In addition to basic machinery, advanced options like crimping machines are essential for achieving secure connections in wire harnesses. These machines vary in complexity, ranging from manual crimpers for smaller operations to automated systems capable of handling large volumes with consistent speed and accuracy. Moreover, testing equipment, such as continuity testers and insulation resistance testers, play a vital role in ensuring that the finished product meets industry standards. By investing in the proper equipment, manufacturers can enhance their production capabilities and ensure the reliability of their wire harnesses.

When evaluating the cost-effectiveness of wire harness manufacturing solutions, it’s essential to focus on several key factors. First, consider the initial investment in manufacturing equipment. While it may be tempting to choose the least expensive option, it’s crucial to evaluate the long-term benefits of features that enhance productivity and reliability. High-quality equipment may come with a higher upfront cost but can result in significant savings through reduced downtime and maintenance needs.

Moreover, assess the scalability of the manufacturing solutions. As the global railway wiring harness market is poised for substantial growth, investing in versatile equipment that can adapt to increasing demand is vital. This flexibility not only ensures ongoing affordability but also positions your business to respond effectively to future market trends. In a rapidly changing environment, the ability to pivot and meet new challenges can make all the difference, reinforcing the importance of a thoughtful approach to equipment selection.

When selecting wire harness manufacturing equipment, the significance of supplier support and warranty cannot be overstated. A strong relationship with your equipment supplier can ensure that you have access to timely assistance, training, and maintenance when issues arise. A responsive supplier not only provides technical support but also helps in optimizing production processes. This relationship can lead to more efficient machinery operation and increased overall productivity.

Moreover, understanding the warranty terms of the equipment is crucial. A comprehensive warranty indicates that the manufacturer stands behind their product, offering protection against defects and potential issues. It also reflects the supplier's confidence in their equipment's reliability and durability. A solid warranty can save your business from unexpected repair costs and downtime, allowing for smoother production runs. Therefore, when evaluating wire harness manufacturing equipment, prioritize suppliers who provide robust support and favorable warranty conditions to safeguard your investment and enhance operational efficiency.

| Tip | Description | Supplier Support | Warranty Duration |

|---|---|---|---|

| 1. Evaluate Your Production Needs | Identify the volume and complexity of wire harnesses you plan to manufacture. | Confirm supplier’s ability to provide training and ongoing support. | 1-3 years. |

| 2. Assess Equipment Specifications | Check the technical specifications and compatibility with your production set up. | Ask for detailed documentation and technical support options. | 2-5 years. |

| 3. Research the Manufacturer’s Reputation | Look for reviews and testimonials to ensure reliability and quality. | Verify their customer service record and service availability. | 3 years. |

| 4. Compare Pricing | Obtain quotes from multiple suppliers while considering equipment features. | Evaluate cost against the level of support offered. | 1-2 years. |

| 5. Review Warranty and Service Agreements | Understand warranty terms and what is covered in case of failure. | Ensure easy access to replacement parts and service support. | 5 years. |

When evaluating manufacturing equipment for wire harness production, assessing technological compatibility is crucial. Different power ranges—low (up to 5W), medium (5W-15W), and high (15W and above)—require distinct considerations regarding the components used, particularly transmitter ICs and receiver ICs. For example, low power systems may lean towards simpler designs that prioritize efficiency, while high power applications might necessitate advanced features to handle increased thermal output and electrical demands.

The market for wireless charging ICs is expanding rapidly, reflecting the growing demand across various applications, from consumer electronics to automotive solutions. Conducting a thorough analysis of the semiconductor market reveals that by 2031, the global market size is projected to reach substantial figures, driven by the continuous integration of digital technologies into manufacturing processes. Companies must adapt to these changes by testing the compatibility of their hardware and software systems, ensuring seamless integration that enhances operational efficiency and productivity.