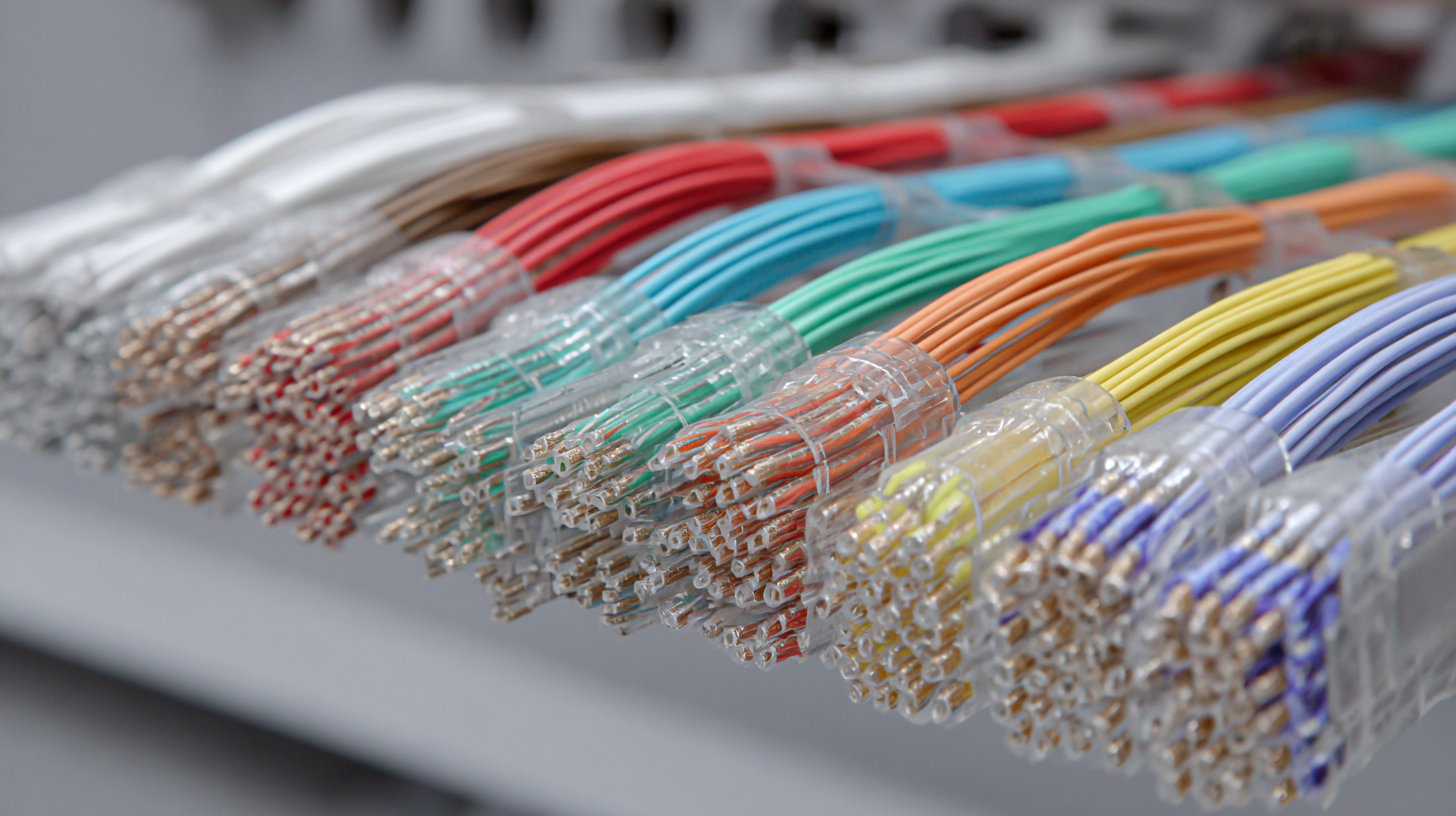

As the demand for advanced electrical systems continues to rise across various industries, the process of wire harness assembly is evolving dramatically. This evolution is driven by a blend of innovative technologies and emerging trends that promise to enhance efficiency, reduce costs, and improve overall quality. With the integration of digital tools such as automation, artificial intelligence, and data analytics, manufacturers are finding new ways to streamline their wire harness assembly processes. Furthermore, the push for sustainability and the growing complexity of electrical architectures necessitate a rethinking of traditional practices. In this context, understanding the latest innovations and practical tips for optimizing wire harness assembly becomes crucial for industry stakeholders aiming to stay competitive. This article will explore these key trends and provide valuable insights into how businesses can adapt to the changing landscape of wire harness assembly.

The wire harness assembly industry is undergoing a significant transformation driven by emerging technologies. According to a recent report by MarketsandMarkets, the global wire harness market is projected to reach $55.97 billion by 2026, growing at a CAGR of 6.73% from 2021. This growth is largely attributed to advancements in automation and smart manufacturing, which are reshaping assembly processes. Robotics and automated systems are being increasingly integrated into production lines, reducing assembly time and minimizing human error. For instance, the use of collaborative robots (cobots) can enhance flexibility, allowing for easier adjustments to production schedules without extensive downtime.

In addition, the adoption of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is revolutionizing wire harness assembly. A study by Gartner predicts that by 2025, over 75 billion devices will be connected to the IoT, empowering manufacturers with real-time data that can optimize assembly workflows, enhance quality control, and improve inventory management. These technologies not only streamline processes but also yield significant cost savings, as they allow companies to predict maintenance needs and reduce waste through efficient resource allocation. The integration of these innovations is setting a new standard in the industry, paving the way for more efficient and sustainable production practices.

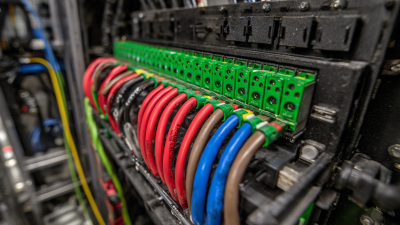

In the rapidly evolving landscape of wire harness assembly, automation plays a pivotal role in enhancing production efficiency. By integrating advanced technologies such as robotics and artificial intelligence, manufacturers are able to streamline their processes, reduce human error, and achieve higher precision in assembly tasks.

Automated systems can handle repetitive tasks at a much faster rate than manual labor, allowing for increased output and reduced operational costs. This shift not only improves productivity but also elevates the overall quality of the end product.

Moreover, the implementation of automation facilitates greater flexibility in production. Manufacturers can adapt to changing customer demands and customize wire harness systems with ease. Smart automation technologies enable real-time monitoring and data analysis, empowering manufacturers to optimize their workflows and identify potential bottlenecks in the assembly process. As the industry continues to embrace these innovations, the future of wire harness assembly appears promising, with automation at the forefront of driving efficiency and meeting the dynamic needs of the market.

The wire harness manufacturing industry is on the cusp of a significant transformation, driven by an increasing emphasis on sustainability practices. Renewable energy sources such as solar, wind, and hydropower are becoming essential, not only for powering production but also for crafting eco-friendly manufacturing methods. As companies strive to reduce their carbon footprints, integrating sustainable materials and processes into wire harness assembly is seen as a crucial step toward market growth and environmental responsibility.

Digital twin technology is emerging as a powerful tool in this evolution, enabling manufacturers to simulate and optimize their production processes in real-time. This innovation allows for more efficient use of resources, reducing waste, and enhancing the agility of manufacturing operations. By embracing these advancements, the wire harness industry positions itself to meet future demands while actively contributing to a more sustainable planet. The shift towards smart manufacturing, as highlighted by initiatives across various sectors, demonstrates that innovation and sustainability can go hand-in-hand, shaping a resilient and responsible market landscape.

| Trend | Description | Impact on Sustainability | Projected Growth (2023-2028) |

|---|---|---|---|

| Eco-Friendly Materials | Utilizing biodegradable and recycled materials for wire harnesses. | Reduces plastic waste and promotes circular economy. | 15% increase |

| Automation in Assembly | Implementing robotics and AI in wire harness assembly processes. | Minimizes waste through precision and efficiency. | 20% increase |

| Customizable Solutions | Offering tailored wire harness solutions to meet specific client requirements. | Less scrap and optimized material usage. | 10% increase |

| Smart Wire Harnesses | Integration of sensors and IoT technology in harnesses for monitoring. | Promotes proactive maintenance and reduces resource waste. | 25% increase |

| Supply Chain Transparency | Enhanced visibility and traceability of materials used in manufacturing. | Improves ethical sourcing and reduces environmental impact. | 18% increase |

The integration of the Internet of Things (IoT) is transforming wire harness assembly operations, paving the way for increased efficiency and productivity. According to a report by MarketsandMarkets, the global IoT in manufacturing market is projected to reach approximately $70 billion by 2026, driven by demands for greater operational efficiency and enhanced supply chain management. The application of IoT technologies in assembly processes enables real-time monitoring of equipment performance and product quality, which significantly reduces downtime and waste.

With the increasing complexities of wire harness systems, leveraging IoT allows manufacturers to implement predictive maintenance strategies. By utilizing sensors and data analytics, companies can proactively address equipment malfunctions before they impact production. A study by Deloitte highlights that manufacturers implementing IoT solutions can improve their operational efficiency by up to 20%. Additionally, IoT facilitates seamless communication between machinery and assembly lines, simplifying workflows and enabling quicker responses to issues as they arise. As this technology continues to evolve, its role in streamlining wire harness assembly operations will likely become even more critical.

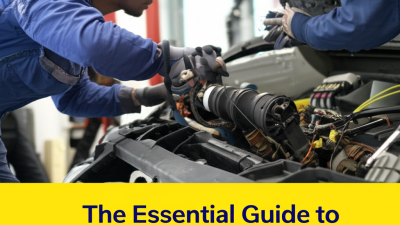

The future of the wire harness assembly industry is poised for significant transformations driven by evolving market trends and consumer demands. As technology advances, there's an increasing emphasis on sustainability and efficiency, pushing manufacturers to innovate their processes. This shift is reflective of broader consumer expectations for environmentally friendly products and practices, influencing the types of materials and methods used in wire harness assembly.

Furthermore, with the rapid growth of automation and artificial intelligence, wire harness manufacturers are integrating these technologies to enhance production capabilities. The demand for smart products, including electric vehicles and smart home devices, is increasingly shaping the specifications and complexity of wire harnesses. This market evolution underscores the need for adaptability and strategic foresight among manufacturers to meet the dynamic demands of consumers and stay competitive in a swiftly changing landscape.