In the ever-evolving landscape of manufacturing, the significance of electrical harness assembly cannot be overstated. As the backbone of modern electrical systems, quality assembly techniques are crucial for ensuring reliability and efficiency across various industries, from automotive to aerospace. According to a recent report by Market Research Future, the global electrical harness market is projected to reach USD 200 billion by 2025, driven by the increasing demand for advanced electronics and the integration of smart technologies. This underscores the need for manufacturers to refine their assembly processes to meet rising industry standards.

To excel in electrical harness assembly, mastering the latest techniques is vital, not only to enhance product quality but also to reduce costs and lead times. A 2023 study published by the International Journal of Advanced Manufacturing Technology highlights that companies employing best practices in harness assembly can achieve up to 30% reductions in manufacturing errors. As we delve into our "Top 10" tips, these insights aim to equip professionals with the necessary skills and knowledge to optimize their electrical harness assembly processes. By focusing on precision, technique, and efficiency, manufacturers can significantly boost their competitiveness in a rapidly growing market.

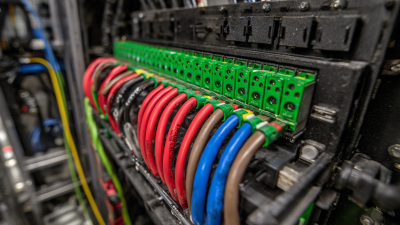

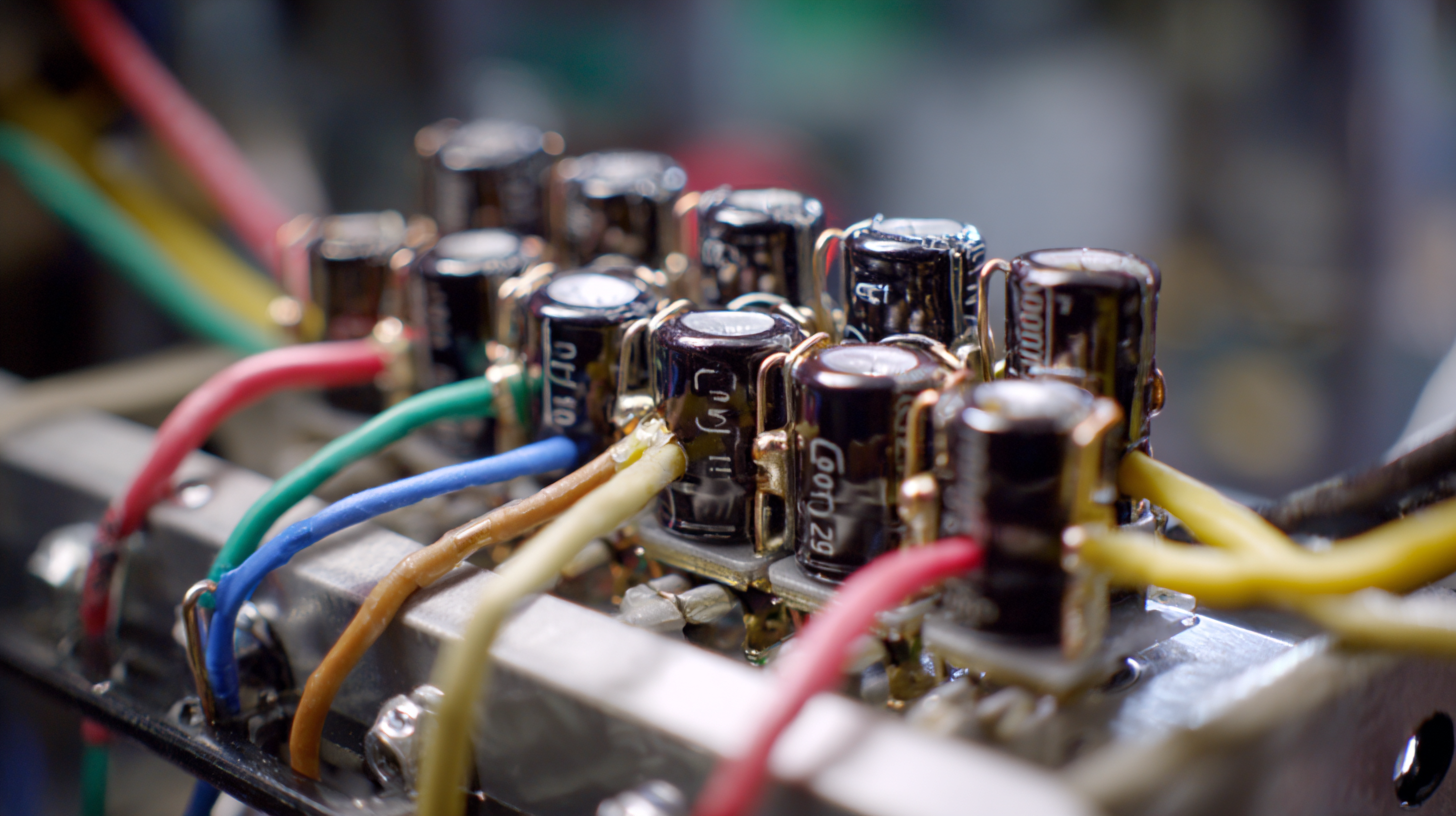

Understanding the components of electrical harnesses is crucial for efficient assembly techniques. Electrical harnesses consist of various components, including wires, connectors, terminals, and protective coverings, each playing a vital role in ensuring reliable performance. Wires are typically made of copper, which is favored for its excellent conductivity and durability. Connectors facilitate the connection between different electrical circuits, while terminals provide a secure means to connect wires to components or devices. Protective coverings shield these components from environmental factors and mechanical stress, crucial in automotive and other applications.

Understanding the components of electrical harnesses is crucial for efficient assembly techniques. Electrical harnesses consist of various components, including wires, connectors, terminals, and protective coverings, each playing a vital role in ensuring reliable performance. Wires are typically made of copper, which is favored for its excellent conductivity and durability. Connectors facilitate the connection between different electrical circuits, while terminals provide a secure means to connect wires to components or devices. Protective coverings shield these components from environmental factors and mechanical stress, crucial in automotive and other applications.

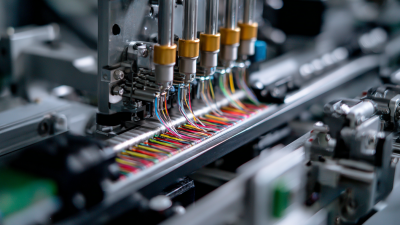

As the automotive industry transforms, particularly with the rise of electric vehicles, the demand for sophisticated wiring harness solutions continues to grow. The global automotive wiring harness market is projected to reach USD 125.48 billion by 2030, which underscores the necessity for understanding these components in depth. Additionally, recent innovations, such as automation in harness manufacturing, are enhancing productivity and ensuring precision in component assembly. These advancements highlight the importance of mastering electrical harness assembly techniques to meet the evolving needs of the industry.

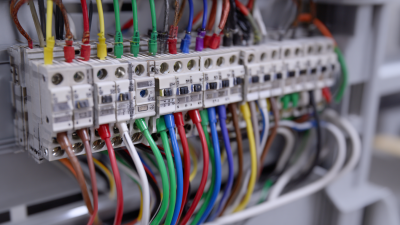

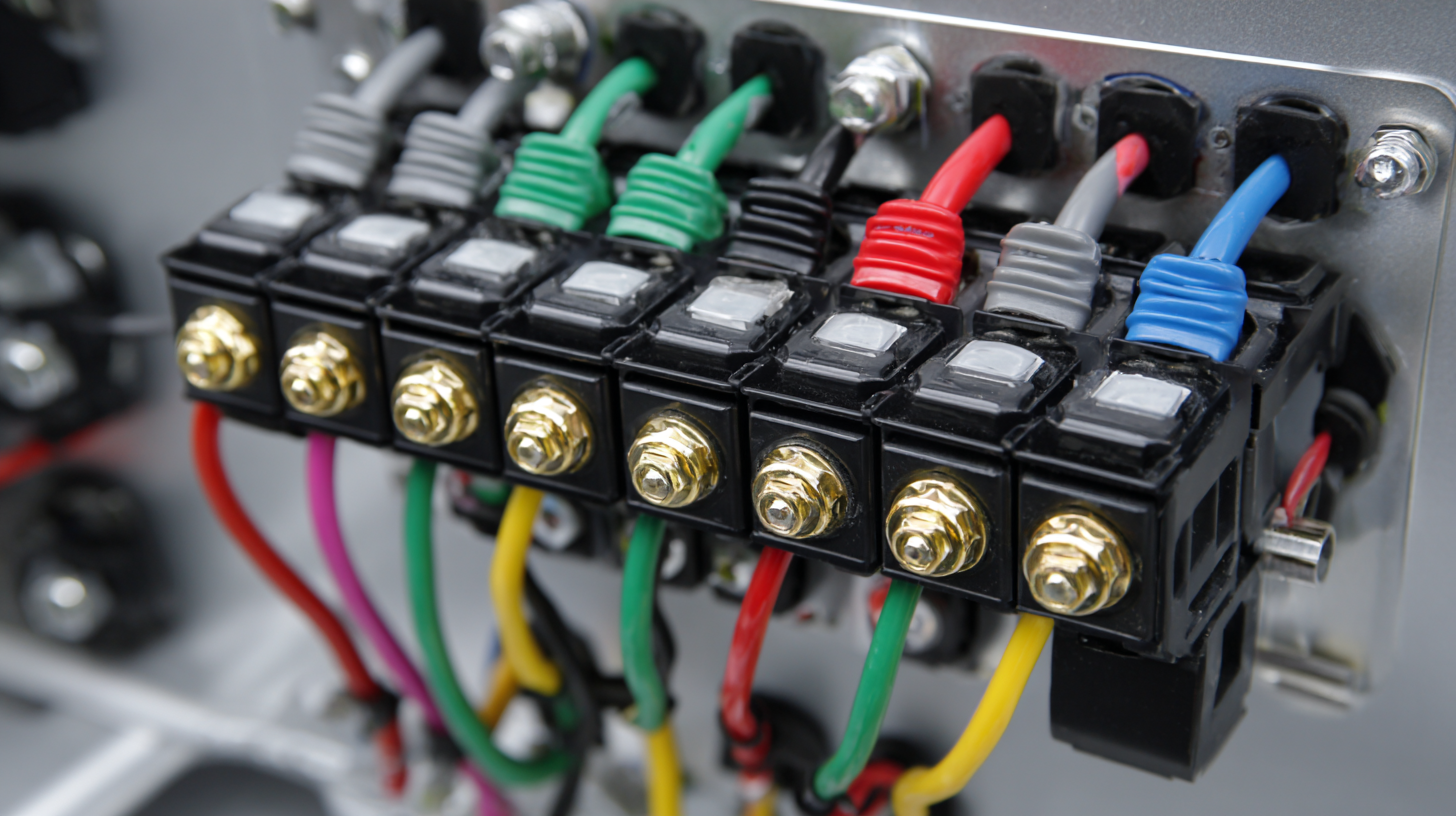

Choosing the right tools is crucial for efficient electrical harness assembly. An optimal toolkit should include wire strippers, crimping tools, and a reliable soldering iron. Wire strippers are essential for cleanly removing insulation from wires without damaging the conductor. This ensures a secure and efficient connection during assembly. Crimping tools come in various sizes and types, allowing for precise connections depending on the gauge of the wire and the type of terminal used. Selecting a high-quality crimping tool can drastically reduce the risk of faulty connections, which is particularly important in applications requiring high reliability.

In addition to strippers and crimpers, incorporating diagnostic tools such as multimeters can significantly enhance the assembly process. A multimeter allows for quick checks of wire continuity and ensures that connections are secure before finalizing the harness. Furthermore, investing in a good heat gun is beneficial for applications requiring heat-shrink tubing, providing additional protection and insulation for the connections. Overall, assembling a well-rounded toolkit tailored to the specific requirements of harness assembly not only streamlines the process but also contributes to the overall quality and durability of the final product.

Accurate wiring and termination are foundational to the integrity of electrical harness assembly. According to a report by the International Electrotechnical Commission (IEC), up to 30% of electrical failures in automotive applications can be traced back to poor wiring techniques and inadequate terminations. This statistic underscores the importance of mastering precise assembly methods to enhance both reliability and performance. Techniques such as proper wire stripping, utilizing the correct crimping tools, and adherence to industry-specific standards, like the IPC/WHMA-A-620, can significantly reduce the incidence of errors during assembly.

Furthermore, implementing quality control measures during the assembly process is crucial. Data from the Society of Automotive Engineers (SAE) indicates that harness assembly processes that incorporate rigorous testing protocols experience a 40% decrease in failure rates. By adopting systematic approaches that include visual inspections and automated testing solutions, manufacturers can ensure that wiring and terminations meet stringent specifications. A focus on continuous training for assembly line workers also fosters a culture of quality, leading to more skilled technicians who can implement best practices seamlessly in their operations.

In today's competitive landscape, the importance of quality assurance (QA) in electrical harness assembly cannot be overstated. As industries increasingly rely on sophisticated technologies, implementing rigorous testing protocols becomes crucial to ensure product reliability and safety. According to recent insights from the QA Summit 2025, organizations must focus on integrating advanced quality practices, including early-stage testing and leveraging AI tools, to enhance product outcomes in manufacturing processes.

A noteworthy trend in the QA field is the adoption of continuous improvement methodologies, such as Kaizen, which promote efficiency and foster innovation within QA teams. The philosophy encourages regular assessment and optimization of processes, which can dramatically elevate the overall quality of electrical harness assemblies. Furthermore, leveraging cloud-based testing solutions has been shown to enhance operational resilience. This shift not only assists firms in maintaining compliance with industry standards but also accelerates their ability to adapt to market changes, as evidenced by recent reports highlighting increasing demands for agile QA processes in the manufacturing sector.

| Tip Number | Tip Description | Best Practice | Quality Assurance Technique |

|---|---|---|---|

| 1 | Use the Right Tools | Invest in high-quality assembly tools for precision. | Regularly calibrate tools to ensure accuracy. |

| 2 | Follow Wiring Diagrams | Reference diagrams for assembly layout. | Cross-check completed assemblies against diagrams. |

| 3 | Maintain a Clean Workspace | Keep workspace organized to minimize errors. | Conduct daily clean-ups to ensure quality. |

| 4 | Properly Strip Wires | Use wire strippers to avoid damage. | Inspect stripped wires for integrity. |

| 5 | Utilize Quality Connectors | Select connectors suited for the application. | Test connectors for proper fit and functionality. |

| 6 | Secure Cables Properly | Use cable ties and clips to prevent movement. | Inspect cable security during assembly and in use. |

| 7 | Label Wires Clearly | Use labels to identify wire functions. | Verify labels are correctly placed and legible. |

| 8 | Conduct Electrical Tests | Test for continuity and shorts before sealing. | Document test results for quality records. |

| 9 | Implement Traceability Systems | Keep records of materials used in assemblies. | Regular audits of traceability systems for effectiveness. |

| 10 | Provide Regular Training | Update skills and knowledge through ongoing training. | Evaluate training effectiveness through assessments. |

In the assembly of electrical harnesses, safety considerations are paramount to ensure a secure and efficient working environment. Proper personal protective equipment (PPE) should always be worn, including gloves and goggles, to safeguard against potential hazards like electrical shocks and injury from sharp components. Additionally, it’s crucial to maintain a clean and organized workspace to prevent accidents caused by tripping or misplacing tools and materials.

When mastering electrical harness assembly techniques, practitioners should be mindful of several essential tips. Firstly, always follow standard operating procedures to ensure consistency and longevity in the harnesses produced. Secondly, conduct regular training sessions to keep the team updated on the latest safety protocols and assembly techniques. This fosters a culture of safety and proficiency, reducing the likelihood of errors that could lead to hazardous situations. Lastly, invest in quality tools and materials, as this significantly impacts both safety and the overall quality of the harness assemblies. By prioritizing these practices, one can create a robust framework for safe and effective electrical harness assembly operations.