In the automotive industry, the wire harness assembly plays a critical role in ensuring the functionality and safety of vehicles. With over 30% of automotive failures attributed to electrical issues, optimizing the wire harness assembly process can significantly enhance vehicle performance and reliability. According to a recent report from MarketsandMarkets, the global wire harness market is projected to grow from $62.99 billion in 2021 to $85.62 billion by 2026, highlighting the increasing demand for efficient manufacturing processes. Moreover, advancements in technology are driving the evolution of wire harness assemblies, with the introduction of automated solutions projected to reduce assembly time by up to 25%. By prioritizing efficiency and safety in wire harness assembly, manufacturers not only streamline production but also contribute to the overall quality and safety standards of modern vehicles, making it an essential consideration for any automotive manufacturer aiming for success in today's competitive landscape.

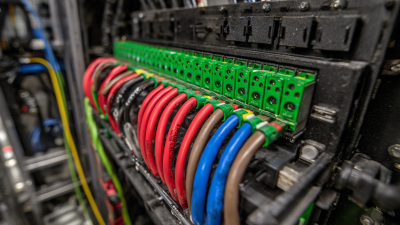

In the automotive industry, wire harnesses play a crucial role in connecting various electronic components necessary for efficient vehicle operation. Understanding the different types of wire harness components is essential for enhancing both performance and safety in vehicles. Wire harnesses typically include wires, connectors, terminals, and protective coverings, each serving a distinct function. For instance, wires transmit electrical signals or power, while connectors facilitate the connection between different electronic modules, ensuring seamless communication and functionality.

Moreover, automotive applications increasingly rely on complex systems such as power sliding doors, which require specialized wire harness assemblies. These systems consist of electric motors and electronic control units, all intricately linked through their harnesses. With advancements in both internal combustion engine (ICE) and electric propulsion technologies, the demand for efficient wire harness designs is growing. This not only boosts the overall efficiency of the vehicle but also enhances safety by reducing the risk of electrical failures or malfunctions in critical systems. Understanding the specific components and their interactions within wire harness assemblies is essential for manufacturers aiming to improve vehicle performance and reliability in today’s competitive automotive landscape.

The automotive industry is rapidly evolving, and the assembly of wire harnesses plays a vital role in enhancing vehicle efficiency and safety. Advanced manufacturing techniques, such as automated assembly systems and robotics, are becoming essential in streamlining wire harness production. According to a report by the International Society of Automotive Engineers (SAE), automating wire harness assembly can improve production speed by up to 30% while significantly reducing labor costs. These innovations not only accelerate the assembly process but also enhance the accuracy and consistency of the wiring systems used in modern vehicles.

Tips for manufacturers looking to improve wire harness assembly include investing in modular assembly systems that allow for flexibility in design and function. Additionally, incorporating real-time data analytics can help identify production bottlenecks, enabling teams to implement immediate solutions. Utilizing advanced materials like lightweight composite wires can also contribute to overall vehicle efficiency.

Moreover, staying updated with the latest industry standards and certifications can minimize safety risks. Studies indicate that compliance with ISO/TS 16949 can lead to a 20% reduction in warranty claims related to electrical failures. By prioritizing advanced manufacturing techniques and continuous improvement, companies can significantly boost both efficiency and safety in wire harness assembly.

Measuring efficiency in automotive wire harness production requires the identification of key metrics that directly impact both productivity and safety. One critical metric is the production cycle time, which measures the duration from the start of assembly to the completion of the wire harness. By analyzing these cycle times, manufacturers can pinpoint bottlenecks in the assembly process, implement process improvements, and ultimately reduce lead times. Additionally, first-pass yield, which reflects the percentage of units produced correctly without rework, is essential for maintaining high-quality standards while increasing efficiency.

Another important metric is labor productivity, which assesses the output per labor hour in wire harness assembly. By monitoring this figure, organizations can identify areas where workforce training and resource allocation may enhance performance. Furthermore, defect rates and return rates are crucial for understanding the impact of efficiency on customer satisfaction and safety. By systematically evaluating these metrics, automotive manufacturers can continuously refine their wire harness assembly processes, ensuring both high efficiency and the safety of the final product.

Wire harness assemblies play a critical role in the automotive industry, serving as the nervous system that connects various electrical components. Adhering to safety standards is paramount, as these assemblies must withstand rigorous conditions while ensuring the vehicle operates safely. Regulatory bodies like the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE) provide frameworks that guide manufacturers in creating reliable wire harnesses. Compliance with these standards not only mitigates risks but also enhances the overall quality of automotive electrical systems.

Quality control processes in wire harness assembly are essential to maintain high safety standards. Manufacturers employ various testing methods, such as insulation resistance and continuity testing, to verify the integrity of each wire harness before it is installed in vehicles. Additionally, implementing stringent inspection protocols throughout the production process ensures that any defects are identified early, reducing the likelihood of failure in the field. Emphasizing quality control not only boosts operational efficiency but also reinforces consumer trust in automotive safety features, ultimately leading to enhanced vehicle performance and longevity.

The automotive industry is undergoing a transformative phase, largely influenced by emerging technologies in wire harness design and assembly. Innovations such as advanced materials, modular designs, and automation are significantly enhancing the efficiency and safety of wire harness systems. These technologies not only streamline the assembly process but also improve durability and reduce weight, resulting in better fuel efficiency and performance of vehicles.

Moreover, the integration of smart manufacturing practices, including the use of Internet of Things (IoT) devices and artificial intelligence, is revolutionizing wire harness production. These technologies enable real-time monitoring and data analysis, which help in identifying potential issues proactively and ensuring high-quality standards throughout the assembly process. As the automotive sector continues to evolve, embracing these emerging technologies will be crucial for companies aiming to stay competitive and meet the growing demand for safer, more efficient vehicles.

This chart illustrates the projected improvement in efficiency of wire harness assembly in the automotive industry over the years from 2020 to 2024. As emerging technologies continue to evolve, we can expect significant advancements in efficiency, thereby enhancing overall safety and productivity within the sector.