In the world of electronics and machinery, cable harness design plays a pivotal role in ensuring optimal performance and reliability of systems. As revealed in a recent industry report by MarketsandMarkets, the global cable harness market is expected to grow from $92.79 billion in 2021 to $118.36 billion by 2026, driven by increasing demand in sectors such as automotive, aerospace, and telecommunications. Effective cable harness design not only enhances the durability and functionality of electronic devices but also plays a crucial part in minimizing electromagnetic interference and facilitating easier maintenance. In this essential guide, we will explore best practices for cable harness design, equipping engineers and designers with the knowledge necessary to maximize performance and reduce costs, ultimately leading to more efficient systems that meet the demands of modern technology.

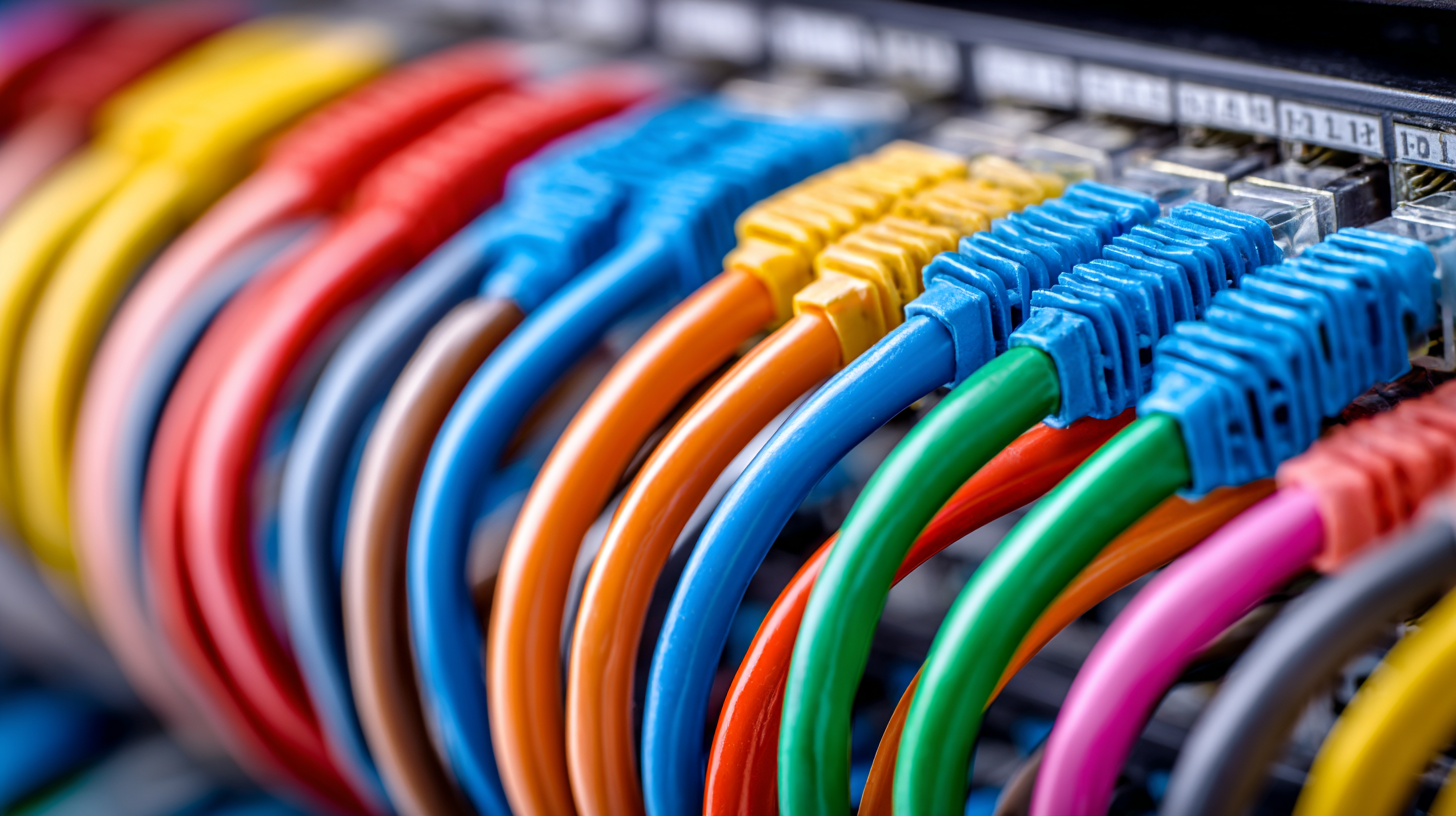

Cable harness design is a crucial aspect of electrical engineering that can greatly influence the performance and reliability of a system. For beginners, understanding the basics of cable harness design involves familiarizing yourself with essential components, materials, and layout principles. A cable harness typically consists of multiple wires bundled together, providing organization and protection for electrical systems. The selection of appropriate materials, including insulation types and connector styles, is fundamental to ensure durability and efficiency.

When designing a cable harness, one must also consider factors such as bending radius, cable strain relief, and environmental conditions. Properly managing these elements not only enhances the longevity of the harness but also reduces the risk of electrical failures. Beginners should learn to create clear schematic diagrams, as these visual aids can simplify complex layouts and ensure that each wire serves its intended purpose effectively. By grounding oneself in these fundamental concepts, one can lay the foundation for creating effective and reliable cable harnesses that meet specific project needs.

In the evolving landscape of cable harness design, selecting the right materials and components is paramount for achieving optimal performance. Essential materials like copper and specialized polymers are widely utilized in the construction of cable harnesses. Copper, in particular, has long been the preferred choice due to its excellent conductivity and durability. It plays a critical role in applications ranging from automotive wiring to renewable energy systems, which are increasingly integral to sustainable practices.

As the demand for renewable energy sources, such as solar and wind, grows, the focus on robust and reliable wiring solutions becomes even more pronounced. Effective cable harness construction not only enhances the performance of energy systems but also supports their longevity. In this context, incorporating advanced materials like heat-resistant and environmentally friendly insulation can significantly improve the efficiency of cable harnesses, ensuring they meet the rigorous demands of modern applications. By prioritizing high-quality materials, designers can create innovative solutions that contribute to a more sustainable future while addressing the challenges posed by increasing energy demands.

| Component Type | Material | Application | Performance Characteristics |

|---|---|---|---|

| Wires | Copper | General power distribution | Excellent conductivity, flexible |

| Insulation | PVC | Wire insulation | Good chemical resistance, flame retardant |

| Connectors | Aluminum | Interfacing different circuits | Lightweight, corrosion-resistant |

| Cable Ties | Nylon | Cable management | Durable, weather-resistant |

| Heat Shrink Tubing | Polyolefin | Sealing and insulation | Flexible, provides a water-tight seal |

When planning your cable harness layout, the first step is to conduct a thorough analysis of the requirements specific to your project. This involves understanding electrical specifications, environmental factors, and the intended use of the cable harness. Begin by mapping out all components and their interconnections in a schematic format. This will serve as the foundation for your layout and help identify potential issues such as interference or space constraints early in the design process.

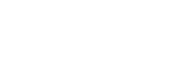

Next, focus on optimizing the arrangement for both functionality and ease of assembly. Consider grouping cables by function and keeping power lines separate from signal lines to minimize noise. Additionally, prioritize a layout that allows for efficient cable routing to reduce strain and wear over time. Employing cable ties, heat shrink tubing, and other securing methods can also enhance reliability while facilitating easier maintenance. Remember that a well-thought-out cable harness layout is essential not just for performance, but also for ensuring safety and longevity in your electrical systems.

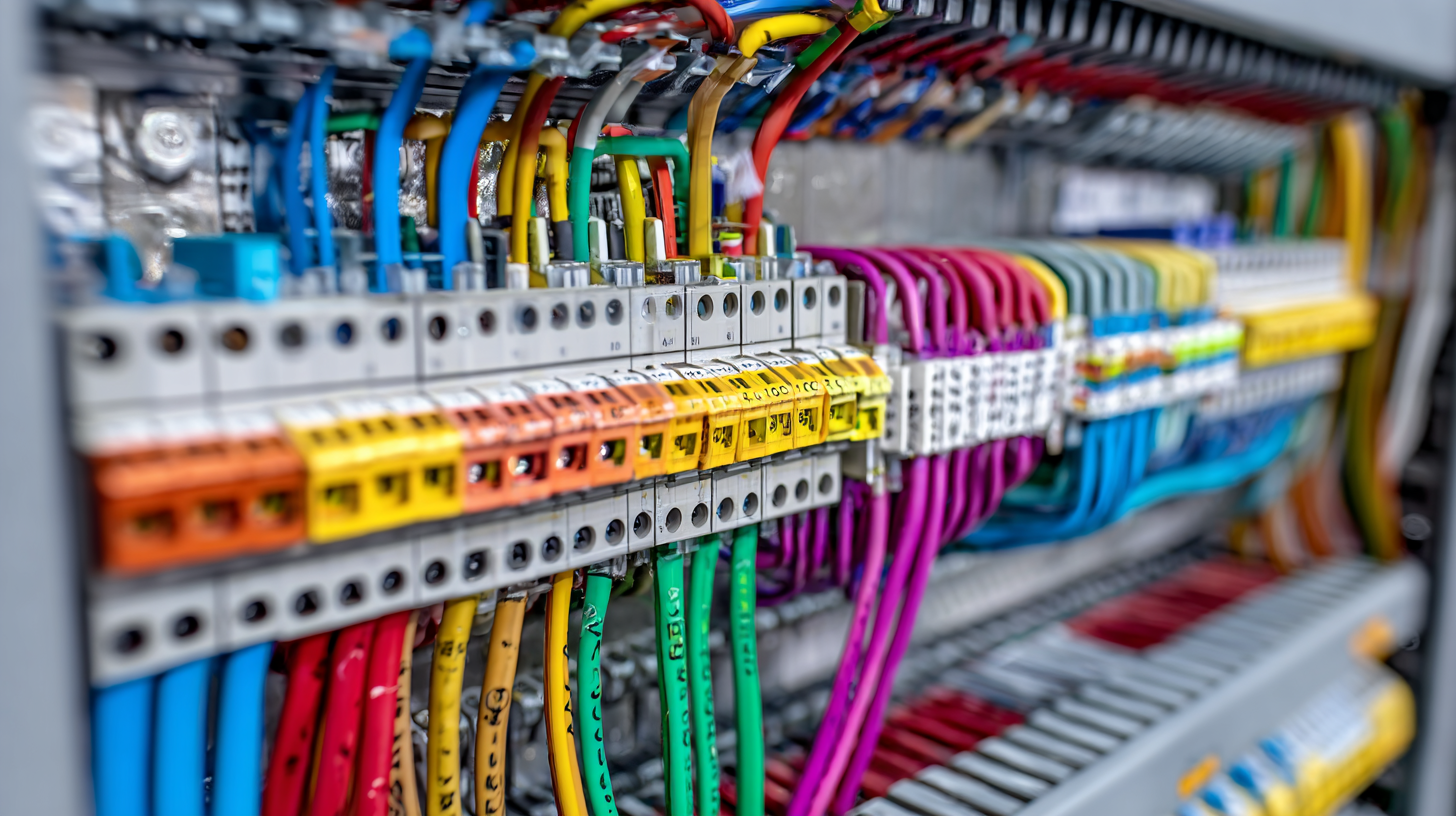

When it comes to cable harness assembly, adhering to best practices is crucial for ensuring optimal performance and longevity of the system. One of the primary considerations is selecting the right materials. High-quality insulation, connectors, and protective sheathing can significantly impact the overall reliability of the cable harness. Additionally, proper organization—using cable ties, clips, and channeling—helps prevent tangling and damage during installation and operation. Ensuring that all components are compatible and tested under the intended environmental conditions further enhances performance.

Installation techniques also play a vital role. It is important to follow a systematic approach when routing and securing the cable harnesses. Maintaining appropriate bend radii and avoiding sharp edges during installation can prevent undue stress on the cables. Moreover, employing strain relief methods at connection points helps mitigate the risk of wear and tear over time. Training the assembly personnel in these techniques ensures consistency and quality in the end product, ultimately leading to a more durable and efficient cable harness system.

When designing cable harnesses, many engineers fall into common pitfalls that can compromise performance and reliability. One of the most frequent mistakes is neglecting to account for the mechanical and environmental stresses the harness will face. Inadequate strain relief can lead to wire fatigue and eventual failure, so incorporating proper bends and securing mechanisms is essential. Additionally, overlooking the effects of temperature changes can result in insulation breakdown, making it vital to select materials that can withstand the intended operating environment.

Another prevalent issue is poor organization and labeling of wires. Without a clear identification system, troubleshooting becomes time-consuming and challenging. It's imperative to establish a labeling convention that is consistent and intuitive, helping to streamline maintenance and repairs. Furthermore, inadequate testing during the design phase can also lead to problems down the line. Implementing thorough testing protocols can help identify potential failures before deployment, ensuring long-term functionality and reducing costly rework later in the process. By avoiding these pitfalls, cable harness designs can achieve optimal performance and reliability.