As we look towards 2025, the landscape of wire and cable assembly is evolving at an unprecedented pace, driven by technological advancements and changing industry demands. This ultimate guide will explore the top trends shaping the future of wire and cable assembly, providing insights and practical strategies for businesses aiming to stay ahead of the curve. From the integration of smart technologies to sustainable practices, understanding these trends is crucial for industry professionals seeking to optimize production processes and enhance product offerings.

In this era of rapid innovation, wire and cable assembly is not only about connecting components but also about enabling smarter, more efficient solutions across various sectors, including automotive, telecommunications, and renewable energy. Stakeholders must adapt to new materials and techniques that improve durability and performance while reducing environmental impact.

This guide will highlight the pivotal trends that will define the wire and cable assembly landscape in 2025, giving readers a comprehensive understanding of what to expect and how to leverage these changes for competitive advantage.

As we look toward 2025, emerging technologies are set to revolutionize the wire and cable assembly sector. Notably, the integration of automation and robotics in manufacturing processes promises significant efficiency gains. According to a recent report from MarketsandMarkets, the global market for automation in manufacturing is projected to reach $214 billion by 2026, driven by advancements in robotics and IoT integration. These technologies enable more precise control over production, minimizing errors and reducing labor costs, thus reshaping the operational landscape.

Furthermore, the demand for high-speed data transmission and the rise of electric vehicles (EVs) are pushing manufacturers to innovate continuously. A report by Mordor Intelligence indicates that the global EV cable market is expected to grow at a CAGR of 34.5% from 2021 to 2026. This surge necessitates the development of specialized wire and cable assemblies that can support faster charging and enhanced performance.

High-performance materials, such as advanced polymers and composites, are becoming essential to meet stringent safety and performance standards in these applications.

High-performance materials, such as advanced polymers and composites, are becoming essential to meet stringent safety and performance standards in these applications.

Additionally, sustainability in the wire and cable industry is gaining traction, with organizations seeking eco-friendly materials and processes. The International Cable and Connectivity Association highlights a growing trend toward recyclable and renewable resources, reflecting a shift in consumer preferences and regulatory pressures. As these technologies and trends converge, they will fundamentally reshape the wire and cable assembly landscape, driving innovation and efficiency in ways previously unimagined.

As the manufacturing sector approaches 2025, sustainability in wire and cable assembly is becoming a crucial focus. Companies are increasingly adopting renewable energy sources like solar, wind, and hydropower to not only reduce their carbon footprint but also to meet the growing demand for eco-friendly products. This shift towards sustainable practices is not just about compliance; it's driving market growth and innovation, with a significant emphasis on developing recyclable and biodegradable materials.

Tips for integrating sustainability into cable manufacturing include investing in research and development to enhance production efficiency and adopting digital technologies to streamline processes. Manufacturers can also benefit from forming partnerships with environmentally conscious suppliers to ensure a sustainable supply chain.

With rising awareness regarding environmental issues, companies must proactively embrace sustainable practices. Industries can utilize eco-friendly materials and implement energy-efficient manufacturing processes. By doing so, businesses not only contribute to global sustainability goals but can also enhance their market position in a competitive landscape.

As we look ahead to 2025, the wire and cable assembly market is poised for significant growth, driven by key market dynamics. The global cable assembly market was valued at approximately USD 178.90 billion in 2024 and is expected to soar to USD 253.81 billion by 2030, reflecting a robust CAGR of 6%. This expansion is largely attributed to escalating demand in industries such as automotive, telecommunications, and industrial applications. With the automotive control cable market projected to reach USD 7.78 billion by 2034, innovation in wire and cable assembly is essential to meet increasing consumer expectations and technological advancements.

Tips: To stay competitive, companies should focus on adopting advanced manufacturing techniques and materials. Integrating smart technology and IoT capabilities can greatly enhance the functionality and reliability of cable assemblies. Moreover, diversifying product offerings to include environmentally friendly options may also give businesses an edge in a market that increasingly values sustainability.

Furthermore, specific segments like RF interconnect market are expected to witness remarkable growth, from USD 36.5 billion in 2025 to USD 75.2 billion by 2035, indicating a substantial demand for specialized cable assemblies. Keeping an eye on such emerging trends will be crucial for industry players looking to capitalize on new opportunities.

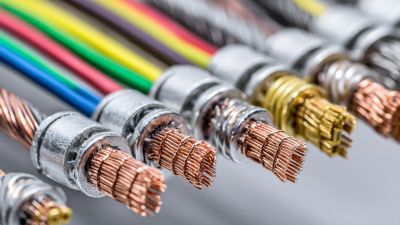

As the wire and cable assembly industry evolves, innovative materials play a crucial role in enhancing cable design and performance. According to a recent report by MarketsandMarkets, the global wire and cable market is projected to reach $303.76 billion by 2025, driven in part by advancements in materials technology. These innovations include the use of high-performance polymers such as polyphenylene sulfide (PPS), which significantly improves thermal stability and chemical resistance. This allows cables to operate effectively in extreme environments, meeting the stringent demands of modern applications.

Another trend in material innovation is the integration of nanotechnology into cable manufacturing. Research indicates that incorporating nanoscale additives can improve the mechanical properties of cables, leading to enhanced durability and flexibility. A study by Grand View Research reveals that the global market for nanomaterials in electrical applications is expected to surpass $25 billion by 2027, underlining the growing importance of these advanced materials in improving cable performance. As manufacturers continue to adopt these cutting-edge materials, the wire and cable assembly sector is poised for significant transformation, offering products that meet the higher expectations of performance, efficiency, and sustainability.

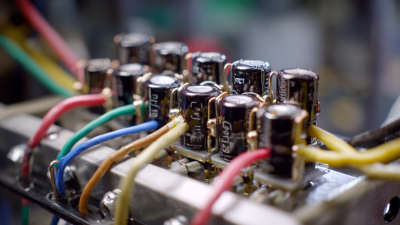

The landscape of wire and cable assembly is evolving rapidly, particularly with advancements in automation and smart manufacturing. These technologies introduce significant efficiencies in the production process, minimizing manual intervention and reducing human error. Automated systems can precisely manage the intricate tasks involved in wire and cable assembly, including cutting, stripping, and termination, which enhances the overall quality and consistency of the final products.

Moreover, the integration of smart manufacturing technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), enables real-time monitoring and data analysis throughout the production cycle. This capability allows manufacturers to optimize their operations by predicting maintenance needs and adjusting workflows dynamically based on performance metrics. As a result, companies not only improve their productivity but also increase their adaptability in response to market demands and customer requirements. These trends are reshaping the future of cable assembly, driving higher standards and creating exciting opportunities for innovation in the industry.